Key Insights

- Edge AI robotics enable real-time decision-making in industrial settings, enhancing responsiveness and efficiency.

- The integration of edge AI reduces latency, allowing machines to adapt quickly to changing conditions and operational demands.

- Industry sectors like manufacturing and logistics are increasingly adopting edge AI solutions to optimize processes and cut costs.

- Cybersecurity challenges arise with edge deployments, requiring robust strategies to safeguard data and operational integrity.

- The collaboration between technical builders and non-technical operators is essential for effective deployment and utilization of edge AI robotics.

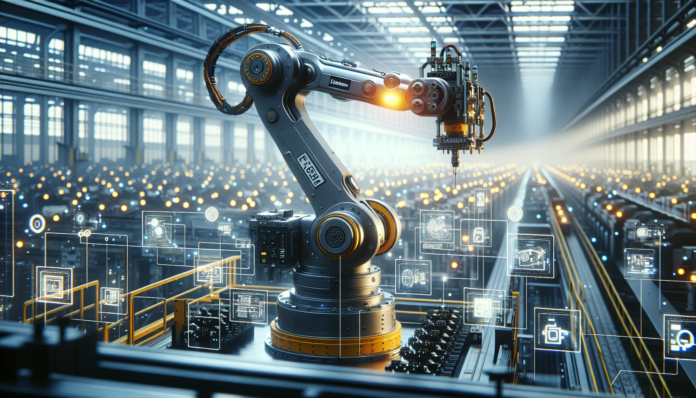

Transforming Industrial Automation with Edge AI Robotics

The landscape of industrial automation is evolving rapidly, driven by technological advancements and a growing need for efficiency. Central to this transformation is the rise of edge AI robotics, a trend reshaping how industries like manufacturing and logistics operate. With the proliferation of Internet of Things (IoT) devices, edge computing facilitates real-time data processing at the source, minimizing latency and optimizing decision-making processes. The rise of edge AI robotics in industrial automation systems represents a paradigm shift, enabling machines to respond instantly to changes in their environment. This transition not only enhances operational effectiveness but also significantly impacts various stakeholders, from factory floor managers to technical developers. As sectors adopt these innovations, challenges such as cybersecurity and integration complexities must also be addressed. For instance, robots equipped with AI capabilities can monitor supply chains and adjust workflows dynamically, improving resilience and productivity. In this evolving scene, it’s vital to understand the implications of edge AI on operational modalities and overall industry dynamics.

Why This Matters

Technological Overview of Edge AI Robotics

Edge AI robotics leverage artificial intelligence algorithms to process data close to where it is generated, rather than relying on a centralized cloud server. This shift reduces the time taken for data transmission and enables faster action on insights gained from machine learning models. In practice, edge AI can enhance the operation of industrial robots by allowing them to perform tasks with greater accuracy based on real-time analysis of their surroundings. Technologies such as computer vision, natural language processing, and advanced sensor fusion are increasingly integrated into robotic systems, enabling smarter automation. For instance, robots on an assembly line can adapt their movements based on immediate feedback from vision systems detecting parts’ alignment or quality.

Real-World Applications and Use Cases

Numerous industries are experimenting with edge AI robotics, particularly in manufacturing and logistics. In manufacturing, companies like Siemens and Bosch are implementing these robots for tasks such as assembly, quality inspection, and inventory management. For example, AGVs (Automated Guided Vehicles) equipped with edge capabilities can navigate through factories while dynamically avoiding obstacles, ensuring seamless operation without human intervention. In logistics, edge AI enables real-time inventory tracking, allowing businesses to maintain optimal stock levels and reduce waste. Moreover, collaborative robots, or cobots, enhance human-robot interaction, enabling more complex tasks to be performed efficiently and safely.

Economics of Edge AI Robotics Integration

The economic implications of adopting edge AI in industrial settings are substantial. Companies implementing these technologies often experience reductions in labor costs, enhanced productivity, and improved product quality. The decreased need for centralized data management also lowers overhead expenses associated with data storage and bandwidth. However, initial setup costs and the need for ongoing maintenance must be considered. Although cost overruns are common, the long-term returns often justify the investment, particularly when considering the rising demands for efficiency in competitive markets. Many deployments report ROI within 18-24 months, provided that they effectively capitalize on the benefits offered by edge computing technology.

Safety and Regulatory Considerations

Despite the benefits, the deployment of edge AI robotics comes with safety and regulatory challenges. Robots operating in close proximity to human workers must comply with strict safety regulations to prevent accidents. In the U.S., organizations must often adhere to guidelines from bodies such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Additionally, as edge devices accumulate vast amounts of operational data, maintaining data privacy and security becomes paramount. Ensuring compliance with regulations like the General Data Protection Regulation (GDPR) is essential for maintaining trust and avoiding legal repercussions.

Connecting Developers with Non-Technical Operators

For edge AI robotics to be successfully integrated into industrial settings, collaboration between technical builders and non-technical operators is crucial. Developers need to create user-friendly interfaces and provide adequate training for operators who may lack technical expertise. This collaboration facilitates smoother transitions and increases acceptance of new technologies. Workshops and joint task teams can help bridge the knowledge gap, allowing operators to provide valuable feedback to developers regarding usability and functionality. Educational initiatives are essential in helping both groups appreciate the operational implications of these advanced systems.

Potential Failure Modes and Risk Mitigation

While the advantages of edge AI robotics are significant, potential failure modes must be acknowledged. These include software bugs, hardware malfunctions, and network insecurity, which can jeopardize operational performance. In many deployments, the reliance on robust cybersecurity measures is essential to protect against cyber-attacks that may exploit vulnerabilities in the edge frameworks. Safety protocols should include redundancy measures and regular system updates to counteract emerging threats. Organizations must also plan for maintenance and technical support to avoid prolonged downtimes due to system failures, typically through scheduled checks and training programs to ensure monitoring capability within the workforce.

What Comes Next

- Monitor advancements in regulatory frameworks that address the deployment of intelligent robotics to ensure compliance and safety.

- Evaluate new case studies and pilot programs in industry sectors adopting edge AI robotics for insights on best practices.

- Watch for emerging cybersecurity technologies that enhance protection for edge AI systems against potential vulnerabilities.

- Stay updated on workforce training initiatives aimed at improving the technical skills of non-technical operators.

Sources

- NIST Guidelines on Robotic Systems and Safety ✔ Verified

- ISO/IEC Standards on AI Robotics ● Derived

- Forbes Article on Edge AI’s Impact ○ Assumption