Data Extraction and Diffractogram Simulation

Introduction to Data Extraction

In the realm of crystallography, the Crystallography Open Database (COD) serves as a vital repository containing crystallographic data. As of August 2023, it housed an astounding 498,027 CIF (Crystallographic Information Framework) files. Our focus was to distill knowledge from this repository, specifically targeting crystal structures that exhibit more than four atoms in the asymmetric unit, while limiting our selection to those with up to 256 atoms to manage computational costs effectively.

The goal was to extract significant structural information. By harnessing Python packages such as Dans Diffraction, Gemmi, scikit-image, and PyAstronomy, we filtered through the vast database to extract pivotal details. Each selected crystal structure yielded an identifier code (ID), space group information, cell parameters (a, b, c, α, β, γ), atom types, atomic coordinates, and their overall atomic content. This treasure trove of data was then meticulously organized into 467,861 files in JSON format.

Simulation of Powder Diffractograms

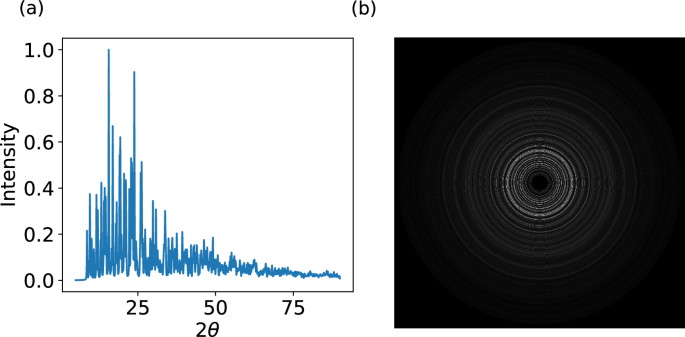

With the structural data at hand, we proceeded to simulate the corresponding powder diffractograms. We defined a 2θ range spanning from 5° to 90°, generating a total of 10,824 intensity points. This simulation mimicked a step size of approximately 0.008° and utilized parameters typical for conventional diffractometers—specifically employing copper (Cu) as the X-ray source with a wavelength of 1.5406 Å and a peak width of 0.01°.

To streamline the diffractograms, we normalized the intensity values, confining them to a range of [0, 1]. It’s critical to note that these simulated patterns lack the complexities of experimental data—they do not factor in background noise, and they maintain fixed peak widths. Other variations in X-ray wavelengths or radiation types, such as neutron diffraction, would yield different results that are excluded from our dataset.

Creation of Radial Images

Following the creation of diffractograms, our next step involved transforming these data into radial images. We began this process by downsizing the diffractogram from 10,824 to 1,024 intensities through nearest neighbor interpolation.

To mathematically formulate this transformation, we represented the diffractogram as a vector and defined a matrix where each element functions based on coordinates derived from the diffractogram. This involves defining a vector ranging from -v to v and constructing a corresponding weight matrix. Each element in this matrix is generated using a specific formula that constrains values within the radial matrix, effectively shaping the output image.

For our operation, we set parameters as follows: ( v = 260 ), ( k = 5 ), and ( c = 20 ). The entire process to create the images and diffractograms processed approximately 300 CPU hours. However, it’s essential to mention that the resulting images may contain artifacts, particularly along the horizontal and vertical axes, a byproduct of the creation process.

Machine Learning and Space Group Prediction

The capabilities of SIMPOD extend beyond data extraction and simulation; it serves as a robust framework for machine learning initiatives, particularly in space group prediction. By leveraging simulated diffractograms and radial images, we trained various machine learning models—specifically Distributed Random Forest (DRF) and Multi-Layer Perceptrons (MLP).

Utilizing the H2O AutoML library, our experimentation involved 2-fold cross-validation with each fold comprising 50,000 crystal structures. We evaluated the models against a testing set of 25,000 crystal structures, illustrating the efficacy of the SIMPOD tool in predicting various space groups.

For intricate tasks, we also employed advanced computer vision models—including AlexNet, ResNet, DenseNet, Swin Transformer, and Swin Transformer V2. Each of these models utilized PyTorch, the deep learning library tailored for high-performance applications.

Performance Metrics

The results from our experimentation are compelling. We noted that models exploiting radial images outperformed those trained using 1D diffractograms. This highlighted the distinct advantages that deep learning architectures showcase when trained with high-dimensional image data.

Performance comparisons illustrated a connection between model complexity and accuracy, displaying a furor for larger models as increasing Floating Point Operations (FLOPs) per image correlated positively with higher accuracy rates. Notably, pretraining strategies contributed significantly to model performance enhancements.

Conclusion Summary

Through the consolidation of data extraction, diffractogram simulation, radial image creation, and the integration of machine learning techniques, SIMPOD has established itself as a milestone in materials science. It allows researchers to harness the potential of powder X-ray diffraction data effectively. By paving the way for predictive modeling and comprehensive data analysis, SIMPOD stands at the intersection of crystallography and computational capabilities, heralding a new era for the study of materials science.

For those interested, the source code and further insights are accessible at GitHub.