“Robust Optical Beam Tracking and Alignment Using Computer Vision in Laser Communication”

Robust Optical Beam Tracking and Alignment Using Computer Vision in Laser Communication

Core Concept of Optical Beam Tracking

Optical beam tracking refers to the process of maintaining the alignment of a laser beam between a transmitter and a receiver. This is crucial in free-space optical (FSO) communication systems, where even minor misalignments can lead to significant data loss. A practical analogy is a spotlight aimed at a moving target; if the spotlight isn’t adequately directed, the target will quickly escape the beam’s illumination, just as data can be lost in a misaligned laser communication.

The impact of effective optical beam tracking is profound in fields such as telecommunications, satellite communication, and UAV operations. High precision in beam alignment can enhance communication stability, reduce error rates, and extend transmission distances, making it a vital area of research and development.

Key Components of the System

A robust laser communication system consists of several core components:

- Laser Transmitter: Generates the optical signal for transmission.

- Receiver Unit: Captures the incoming optical signal and converts it into electrical signals.

- Processing Unit: Analyzes real-time data using computer vision techniques.

- Servo-Controlled Alignment Mechanism: Adjusts the beam’s direction dynamically based on feedback.

These components work interdependently to ensure seamless communication. For instance, if the receiver detects a misalignment, the processing unit analyzes this discrepancy and signals the servo-controlled mechanism to reorient the laser beam, demonstrating how each element plays a crucial role in maintaining communication stability.

Step-by-Step Process of Beam Alignment

The process of maintaining beam alignment involves several sequential steps:

- Image Acquisition: A high-resolution camera captures images of the laser beam at a high frame rate.

- Preprocessing: Noise reduction and contrast enhancement techniques are applied to improve image clarity.

- Feature Extraction: The position of the laser beam is detected using algorithms such as edge detection.

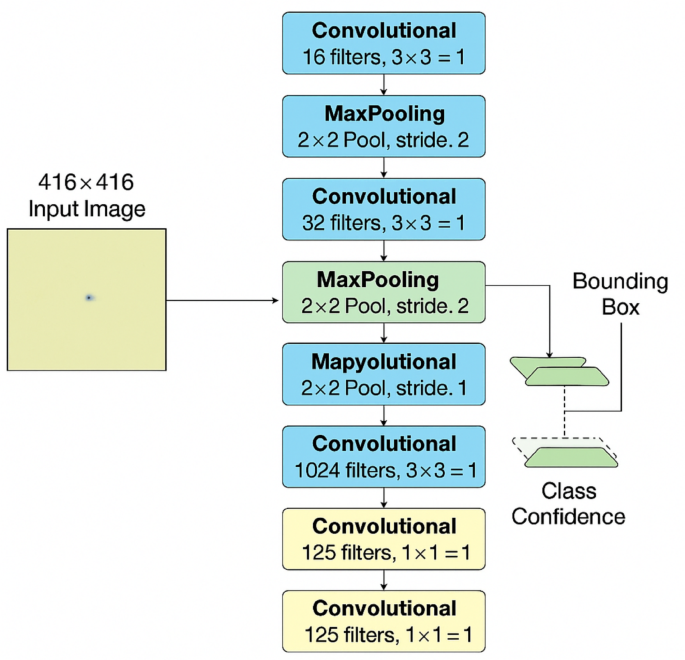

- Tracking: A machine learning model processes the image data to identify the beam’s location accurately.

- Feedback Generation: The detected position is compared against the desired position, generating a control signal for adjustment.

Each step is critical; without accurate image acquisition, subsequent processing can fail to yield reliable results. By using high frame rates, the system can dynamically adjust to environmental changes, ensuring precise alignment.

Practical Scenario: UAV Optical Communication

Consider a UAV equipped with a laser communication system operating in variable atmospheric conditions. The UAV needs to maintain a stable laser link with a ground station while encountering obstacles like wind or turbulence.

In such a scenario, the system continuously captures images using a high-speed camera. When the laser is misaligned, the processing unit analyzes the feedback and predicts the required adjustments. For example, a shift in the UAV’s position could prompt a rapid realignment of the laser beam, thereby maintaining the communication link. The ability to adapt in real time demonstrates the practical value of incorporating computer vision in laser communication systems.

Common Mistakes and Solutions

One common mistake in implementing optical beam tracking systems is underestimating the impact of environmental factors, such as atmospheric disturbances or vibration. Such oversights can lead to significant alignment errors.

To counter this, one effective strategy involves enhancing the robustness of the detection algorithms. Introducing training datasets that include various environmental conditions allows machine learning models to learn how to cope with challenges like motion blur or glare. Moreover, using filters like Kalman can smooth out noisy measurements, leading to more reliable tracking results.

Tools and Metrics Used

Several tools and metrics are essential in developing and evaluating an optical beam tracking system:

- Computer Vision Libraries: Frameworks such as OpenCV for image processing and feature extraction.

- Machine Learning Frameworks: PyTorch or TensorFlow for developing and refining detection algorithms.

- Evaluation Metrics: Precision, recall, and tracking accuracy to assess the system’s performance under various conditions.

These tools provide developers with the necessary means to create efficient optical beam alignment systems and evaluate their effectiveness in real-world applications.

Alternatives and Variations

While computer vision-based tracking is effective, alternative methods exist, such as traditional mechanical or closed-loop control systems.

Pros and Cons:

- Mechanical Systems: Generally more straightforward but slower to adjust, making them less effective in dynamic environments.

- Computer Vision Systems: Offer high-speed adjustments and adaptability, particularly beneficial in rapidly changing conditions but may require more complex setups and algorithms.

Choosing between these methods often depends on specific application requirements, such as the expected range of operation, environmental variability, and the urgency of response needed.

FAQ

What is the primary advantage of using computer vision in optical tracking?

Computer vision enables non-contact, high-speed tracking which is crucial for adapting to dynamic environments without physical interventions.

How can atmospheric conditions affect laser communication?

Atmospheric turbulence can distort the laser beam, leading to degradation in signal quality and increased error rates if not compensated for in real-time.

What is the role of the Kalman filter in this system?

The Kalman filter helps estimate the laser beam’s position by smoothing out measurement noise, providing a more accurate track over time.

How does the PID controller enhance system performance?

A PID controller adjusts based on the proportional, integral, and derivative of the error signal, ensuring smooth corrections to maintain alignment even in changing conditions.