“Revolutionizing Industrial Sorting with Vision and FSM Technology”

Revolutionizing Industrial Sorting with Vision and FSM Technology

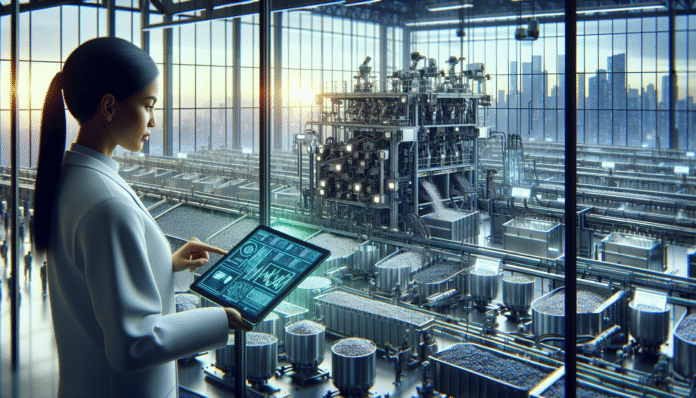

In the modern industrial landscape, efficiency and speed are paramount. Traditional sorting systems often depend on manual labor or simplistic mechanical methods, resulting in errors, delays, and a lack of adaptability. The integration of computer vision and finite state machine (FSM) principles is emerging as a transformative solution, offering precision and efficiency in sorting operations.

Key Components of Vision and FSM-Driven Sorting

Computer Vision: At its core, computer vision refers to the technology that allows machines to interpret and understand visual information from the world. In a sorting context, it enables systems to identify and classify objects through images, significantly reducing human error.

Finite State Machine (FSM): An FSM is a computational model consisting of states and transitions, making it ideal for controlling processes. In sorting systems, FSM helps manage various states like "idle," "detecting," or "sorting," based on specific triggers and conditions.

For example, in a typical sorting scenario, the FSM might dictate that when an object is detected by the camera, the system transitions from the "idle" state to the "detecting" state, proceeding to "sorting" or "rejecting" as required without manual oversight.

The Sorting Process Lifecycle

The sorting process, powered by computer vision and FSM technology, follows a structured lifecycle:

- Initialization: The system begins in the idle state, waiting for objects to be detected.

- Object Detection: The camera captures images of objects. Using trained models, the system determines the properties of each object, such as shape and color.

- Sorting Decision: Based on the identification, the FSM makes a decision: sort, reject, or redirect.

- Execution: The physical actuator moves to sort or reject objects accordingly. Feedback loops confirm operations, and the system continues to the next object.

For instance, in a system where foam blocks in colors of yellow and green are sorted, the camera identifies each color and decides whether to sort it into a designated bin or reject it if it does not meet specific criteria.

Common Pitfalls and Solutions

Several challenges can impede the effectiveness of a vision and FSM-based sorting system:

-

Lighting Conditions: Variability in lighting can impair image capture and, consequently, object detection accuracy. To mitigate this, incorporating controlled lighting ensures consistent performance across various operational environments.

-

Insufficient Model Training: Models that have not been adequately trained may struggle with accurate object classification. Regular updates and retraining with diverse datasets are crucial for maintaining accuracy.

- Complex FSM Logic: Overly complicated FSM implementations can lead to bugs and inefficiencies. Simplifying state definitions and transitions enhances maintainability and system reliability.

By proactively addressing these pitfalls, businesses can enhance the robustness of their sorting solutions, maximizing efficiency.

Practical Application: Case Example

Consider a company that specializes in assembling toy parts. Using a computer vision and FSM-driven sorting system, they integrate components like blocks, wheels, and figures. Each part is scanned and sorted in real-time as it moves along a conveyor.

The system, equipped with a camera and PLC, recognizes parts and sorts them into categories: complete kits, incomplete kits, and rejects. This automation results in quicker assembly line processes, reducing human error and improving overall production times.

Tools and Frameworks in Practice

Tools like Edge Impulse are central to developing machine learning models for object detection and classification. This platform allows users to create a workflow by designing and training models using collected image data.

Meanwhile, programmable logic controllers (PLCs) play a crucial role in interfacing with hardware components like sensors and actuators. These tools work in conjunction to develop a seamless automated sorting solution.

Limitations of such tools can arise in processing power, especially for smaller companies. Therefore, selecting lightweight models and ensuring robust hardware integration is vital in implementing cost-effective systems.

Variations and Alternatives

While computer vision and FSM technology hold significant promise for sorting applications, alternatives exist that might better suit specific requirements. For instance, traditional optical sensors can be advantageous for straightforward, high-speed sorting tasks with limited variability. However, they lack the adaptability that computer vision offers.

Conversely, while implementing deep learning models enhances accuracy in sorting complex shapes and textures, it requires more significant computational resources, which could be a concern for smaller operations.

FAQ

What industries can benefit from vision and FSM-driven sorting?

Many industries, including manufacturing, logistics, and food processing, can enhance operational efficiency through this technology.

How can I simplify the training of my computer vision models?

Utilizing platforms like Edge Impulse facilitates easier model training by providing user-friendly interfaces and guidance through the data acquisition and training process.

What are the costs associated with implementing such a system?

Costs vary widely based on required hardware, software, and infrastructure, but investing in automation often results in long-term savings through increased efficiency.

How do I ensure my system adapts to future changes?

Designing flexible systems with modular components allows for easy upgrades and adaptations as operational needs or technologies evolve.