Key Insights

- Recent research advances in robotics leverage machine learning algorithms

- Enhanced automation capabilities promise significant productivity increases

- Industries such as manufacturing and logistics stand to benefit the most

- Safety regulations and maintenance standards will evolve alongside these technologies

- Small businesses may face obstacles in adopting advanced robotic solutions

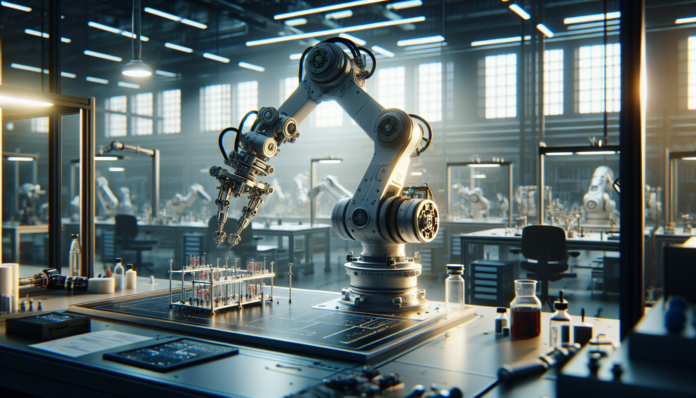

Advancements in Robotics Transform Automation Efficiency

The landscape of robotics and automation is undergoing rapid transformation, thanks in part to innovative research breakthroughs that enhance automation capabilities. A recent study detailing advancements in machine learning algorithms demonstrates their potential to significantly improve robotic performance in various operational settings. Such enhancements are particularly relevant to industries like manufacturing and logistics where efficiency is paramount. The implications of this research go beyond mere productivity gains; they could reshape how companies integrate technology into their workflows. With increasing reliance on automation, businesses must also consider the concrete anchors such as the adaptation of existing machinery and workforce training programs to reap the full benefits of these advancements. Furthermore, this evolution brings forth challenges in terms of regulations and user adoption, especially for smaller enterprises. The study, titled “Recent research breakthrough enhances robotics automation capabilities,” provides a profound basis for understanding these shifts.

Why This Matters

Technological Advancements in Robotics

Machine learning has revolutionized various fields, and robotics is no exception. Algorithms previously used for image recognition or data processing are now being adapted for robotic control systems. These advancements offer robots heightened sensitivity to their environments, allowing them to navigate complex spaces and perform tasks with increased precision. Innovations such as reinforcement learning and adaptive algorithms enable robots to learn from their experiences, adjusting their responses in real time. This flexibility makes them particularly effective in dynamic environments, where traditional programming would struggle.

In practice, consider automated guided vehicles (AGVs) in warehouses. By leveraging advanced machine learning techniques, these AGVs can optimize their routes autonomously, even in fluctuating conditions, such as changing obstacles or varying demand for goods.

Real-World Applications and Deployment

The implications of these technological advancements are profound across various sectors. In manufacturing, robots equipped with advanced automation capabilities can manage repetitive tasks with minimal oversight. For instance, facilities can deploy robotics for assembly lines that adapt in real time to product variations, enhancing efficiency and reducing waste. Logistics firms benefit similarly, utilizing robots for inventory management and sorting, thereby shortening delivery times and cutting operational costs.

The agriculture sector is also witnessing a transformation. Precision farming techniques employ robotics for tasks such as planting, monitoring crop health, and harvesting. These robots can analyze soil conditions and crop health through sensors and data analytics, leading to optimized yield and resource management.

Economic and Operational Implications

The economic impact of enhanced robotics automation capabilities cannot be overstated. As companies adopt these new technologies, they often experience a significant reduction in labor costs and an increase in throughput. For example, manufacturing plants adopting advanced robotic arms can see productivity improvements of up to 40%, allowing for lower production costs and increased competitiveness in the market.

However, the financial implications extend to initial investments in technology. Companies must weigh these costs against potential long-term savings. While larger corporations may find it easier to absorb these costs, small businesses may face challenges related to financing such sophisticated integrations.

Safety and Regulatory Considerations

As robotics technology continues to advance, so too do the safety concerns that accompany its deployment. Regulatory bodies are tasked with ensuring that these machines operate safely alongside human workers. Standards must be established to define acceptable levels of safety in environments where robots operate autonomously or semi-autonomously. Organizations like ISO and IEC are beginning to propose guidelines, but these regulations are still in their infancy.

Moreover, maintenance and operational protocols must keep up with technological changes. Routine checks and balances, cybersecurity measures, and training programs for staff will be essential components of safe robotic operations. The evolution of safety regulations could lead to increased compliance costs, affecting the ROI for companies considering automation upgrades.

Connections for Developers and Non-technical Operators

The consequences of advancements in automation extend to both technical builders and everyday users. For developers and engineers, the continuing evolution of robotic technologies offers an expanding field of opportunities. Specializing in machine learning applications, AI-driven robotics, or software enhancements for control systems can yield profitable career paths. Communities fostered around these topics also stimulate collaboration, leading to the development of new ideas and solutions.

For non-technical operators such as small business owners and students, understanding and leveraging these advancements can enhance operational efficiency and increase future job prospects. Educational institutions are now incorporating robotics and automation concepts into their curricula, preparing the next generation for the workforce demands of tomorrow. Local makerspaces and community technology hubs are serving as platforms for enthusiasts to gain hands-on experience with emerging technologies, bridging the gap between developers and end users.

Failure Modes and What Could Go Wrong

While the advantages of enhanced robotics automation are enticing, numerous potential failure modes must be considered. Safety incidents could arise from malfunctions or miscommunications in robotic operations, emphasizing the need for robust testing and validation protocols. Cybersecurity vulnerabilities are a critical concern as connected devices become more prevalent; breaches could lead to unauthorized control or data theft, posing risks to both systems and users.

Maintenance emerges as another significant challenge. As robotic systems grow increasingly complex, the need for ongoing training for technicians becomes paramount. Organizations must ensure their teams are equipped to troubleshoot and repair sophisticated machines effectively. Additionally, cost overruns could occur if companies underestimate the financial and operational implications of deploying advanced robotic solutions.

What Comes Next

- Monitor regulatory developments in robotics safety standards

- Watch for industry-specific case studies showcasing successful implementations

- Keep track of advancements in machine learning as they apply to robotics

- Follow trends in funding for small businesses to enhance automation capabilities