“Predicting Thermal Contact Resistance Using Deep Learning and Surface Topography”

Predicting Thermal Contact Resistance Using Deep Learning and Surface Topography

Understanding Thermal Contact Resistance (TCR)

Thermal contact resistance (TCR) is a measure of how well two materials conduct heat across their interface. It plays a crucial role in industries where thermal management is vital, such as electronics, aerospace, and automotive sectors. A higher TCR implies less efficient heat transfer, which can lead to overheating and failure of components. For instance, in electronic devices, poor heat dissipation can result in performance degradation or complete malfunction.

Key Variables Influencing TCR

Several factors impact TCR, most notably:

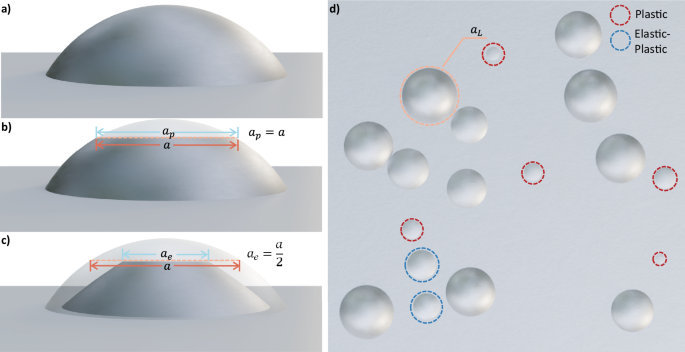

- Surface Topography: The microscopic roughness and texture of the materials significantly affect how they make contact. For example, smoother surfaces generally yield lower TCR as they have more area in real contact.

- Contact Pressure: Increased pressure tends to improve the contact quality, thus reducing TCR. However, too much pressure can lead to material deformation affecting performance.

- Material Properties: The thermal conductivity, hardness, and elastic modulus of the materials involved can also affect TCR.

These variables interact in complex ways, requiring detailed analysis to predict TCR accurately.

Step-by-Step Process for Predicting TCR

To employ deep learning for TCR prediction, a systematic approach needs to be followed:

- Data Collection: Gather extensive datasets regarding material properties and surface topographies. This includes mechanical properties and experimental TCR measurements.

- Surface Characterization: Generate parameters that characterize the surface texture, often using fractal dimensions to model roughness levels accurately.

- Model Training: Utilize a deep learning architecture, such as a Convolutional Neural Network (CNN), to train on the generated dataset. The model learns to correlate surface features to TCR.

- Prediction and Validation: Once trained, the model can predict TCR based on input surface data, which should be validated against experimental results for accuracy.

The comprehensive methodology ensures robust predictions that can be applied across varying conditions.

Practical Example: Application in Electronics

In the electronics manufacturing sector, predicting TCR is vital for thermal interface materials (TIMs) used between heatsinks and components. Poor TCR can lead to component failure due to insufficient heat dissipation. By modeling and optimizing the surface topography of TIMs using deep learning techniques, manufacturers can enhance thermal performance significantly. Research shows that fine-tuning the surface texture can reduce TCR by up to 40%, leading to improved reliability of electronic devices (UN, 2023).

Common Pitfalls and Solutions

One prevalent issue when predicting TCR with deep learning is overfitting, where the model performs well on training data but poorly on unseen data. To mitigate this, utilize techniques such as cross-validation and regularization:

- Cross-Validation: Split the dataset into training and validation sets multiple times to ensure the model generalizes well.

- Regularization: Introduce penalties for overly complex models to enhance generalization.

These strategies help maintain model performance and ensure reliable predictions across various applications.

Tools and Frameworks in Practice

Tools like TensorFlow and PyTorch are widely used for developing deep learning models, including those predicting TCR. TensorFlow supports the building of complex neural networks efficiently, while PyTorch’s flexibility allows for rapid experimentation. However, users must be aware of the computational requirements, as deep learning can be resource-intensive, particularly with large datasets necessary for accurate predictions.

Variations and Alternatives

While deep learning offers considerable advantages in TCR predictions, alternatives exist. Traditional methods like finite element analysis (FEA) can also predict TCR but may require detailed modeling of the physical interface, making them less versatile. In contrast, deep learning models can utilize raw surface data effectively, streamlining the prediction process.

When choosing between these methods, consider factors like data availability, required accuracy, and computational resources. Each approach has trade-offs; for instance, FEA may provide higher granularity in simulations but at the cost of greater complexity and time.

FAQs

Q: What is TCR’s role in thermal management?

A: TCR is crucial as it determines how effectively heat can transfer between materials, impacting performance and reliability in various applications.

Q: How does surface texture affect TCR?

A: Smoother surfaces typically reduce TCR, enhancing thermal conductivity. Uneven surfaces can trap air pockets and increase resistance.

Q: What are some methods to optimize surface roughness?

A: Techniques like surface grinding, coating, or laser treatment can modify surface textures to achieve desired TCR characteristics.

Q: Can deep learning replace traditional predictive methods?

A: While deep learning is powerful, it complements rather than replaces traditional methods, providing faster and often more robust predictions on complex interactions.