Unleashing the Power of Deep Learning in Polymer Property Prediction

The intersection of deep learning (DL) and polymer science is gaining unprecedented attention, merging artificial intelligence (AI) with material science to revolutionize how we analyze and predict material properties. As the transformative capabilities of deep neural networks (DNN) unfold, researchers are leveraging these technologies to advance various applications in polymer science—from evaluating mechanical properties to improving structural optimization strategies.

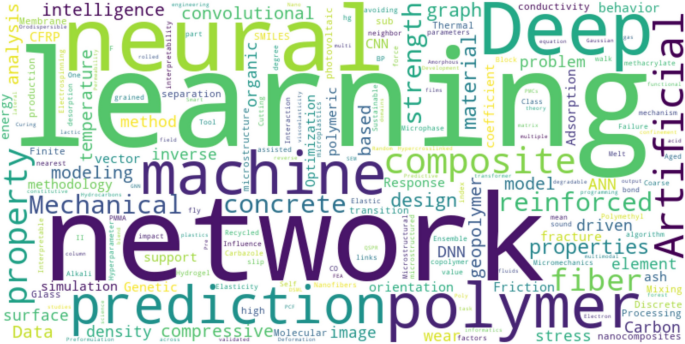

A Glimpse into the Research Landscape

To appreciate the ongoing research trends, consider the word cloud generated from scholarly articles focused on DNN applications in predicting polymer properties. Prominent keywords like “neural,” “network,” “learning,” “polymer,” and “prediction” dominate the visualization, indicating core thematic elements in machine learning and computational modeling. Specific terms, including “geopolymer,” “mechanical,” “strength,” and “analysis,” reflect targeted applications within the realm of polymer science. Such visual insights reveal this field’s interdisciplinary nature, harmonizing concepts from AI, chemistry, and engineering.

Research Contributions: A Global Perspective

The adoption and development of DL techniques in polymer research showcase a global effort, marked by significant contributions from countries like China, the USA, and India. Research publications illustrate the extent of this focus on innovative applications in polymer science—these regions have become hotbeds for these advances. A map representation (Figure 2) visually depicts this distribution, highlighting China’s lead with 257 publications, followed by the United States with 195 and India contributing 77 studies. Such a geographic overview emphasizes the collaborative nature of scientific progression despite international borders.

Challenges in Data Analysis

Despite the profound advancements, challenges persist, particularly in handling heterogeneous data. A notable study by Li et al. introduced a hybrid convolutional neural network (CNN) and multi-layer perceptron (MLP) model designed to predict the mechanical properties of carbon fibers. This innovative approach fuses textual data (macroscopic properties) with visual data obtained from microstructure statistics. Their generated dataset comprises 1,200 stochastic microstructures, pushing forward our understanding of how microstructure influences mechanical properties.

Novel Predictive Models

The study demonstrated that this model—trained on intricate datasets—produced exceptional predictive accuracy, achieving a coefficient of determination as high as (R^2 = 0.991) for the longitudinal modulus. Such impressive results highlight the importance of integrating multi-source data to enhance material property predictions. The two-point statistics used effectively connect microstructure observations to property outcomes, enhancing the interpretability of the predictive model.

Additionally, Bakar et al. utilized DNNs in predicting the density of degradable plastics, drawing from a dataset provided by the Malaysian Palm Oil Board. This study showcased a different dimension of DL’s application through Principal Component Analysis for optimizing model structure—a clear testament to its versatility.

Strides in Material Property Predictions

The landscape of polymer research is rich with diverse studies pinpointing specific properties and behaviors of materials. Notably, Nylon 66 has been a subject of research to decipher its wear mechanisms under cyclic loading. Investigations reveal a significant correlation between load frequency and wear rates, demonstrating how AI methods can successfully replicate experimental findings in predicting wear behavior.

The Rise of Graph Neural Networks

Graph neural networks (GNNs) are gaining traction in molecular property prediction. Their ability to learn from molecular graphs has proven advantageous in areas like drug discovery and material characterization. Hasebe’s Knowledge-Embedded Message Passing Neural Network improved molecular property prediction accuracy significantly by integrating expert knowledge into the learning process, particularly invaluable when data availability is limited.

GNNs provide a structured approach to analyze complex molecular interactions, exemplifying the versatility of neural network architectures in advancing polymer science.

Innovations in Polymer Design

The amalgamation of AI techniques with material science is pushing the boundaries of polymer design. For instance, Zawbaa et al. tackled over 300 variables in the analysis of poly-lactide-co-glycolide nanoparticles, employing sophisticated optimization techniques. Their work emphasizes the potential of machine learning to drive innovations in drug delivery systems.

Moreover, researchers like Aoyagi have combined hierarchical simulations with CNNs, achieving rapid predictions of thermoplastic elastomers’ stress-strain behaviors. This model’s efficiency illustrates how deep learning can expedite the design and testing processes of polymer materials.

Pioneering Approaches in Mechanical Property Assessments

Recent advancements have further refined our approach to predicting the mechanical properties of polymeric materials. Studies like those from Sun et al. applied modified CNNs to predict stress distributions in fiber-reinforced polymers through X-ray micro-CT images. Their approach underscored the high computational efficiency of CNNs, reducing simulation times from hours to mere seconds while enhancing prediction accuracy.

The Role of Optimization in Model Development

The engineering of effective neural network architectures remains a critical aspect of this evolving field. Utilizing genetic algorithms to optimize design configurations has shown promising results. For instance, Hamdia et al. introduced a genetic algorithm that evolved network architectures to enhance predictive capabilities efficiently.

This trend towards optimization aligns with the broader movement within scientific research to embrace computational techniques that can significantly streamline the data handling and model-training processes.

Navigating the Future

The proliferation of DL in the polymer domain signifies a leap forward, fostering an environment ripe for innovation. As demonstrated through various studies, the potential for improving material design, property prediction, and analysis through AI continues to expand. Researchers worldwide are tapping into the synergy between AI and materials science, setting the stage for breakthroughs that may redefine our understanding of material properties and engineering challenges.

The outlined studies and approaches reveal how deep learning not only streamlines processes but also enhances our predictive capabilities in polymer science. As research progresses, the prospect of rapidly developing new materials with tailored properties becomes increasingly feasible, directing us toward an exciting and efficient future in polymer material science.