Comparative Performance Analysis of BEV and HBEV under the EUDC Drive Cycle

The European Urban Driving Cycle (EUDC) serves as a critical benchmark for evaluating electric vehicle (EV) powertrains under diverse driving conditions typically found in urban and highway environments. The EUDC profile comprises varied speed transitions, including sharp accelerations and frequent decelerations that simulate real-world scenarios like stop-and-go traffic and highway cruising.

EUDC Profile Overview

At the outset of the EUDC, the vehicle accelerates from a standstill to approximately 70 km/h in about 60 seconds. After a brief cruising phase, the speed peaks at 100 km/h around 290 seconds, and a maximum speed of near 120 km/h is reached just before 400 seconds. Subsequent rapid decelerations emphasize the need for an agile energy management system. Here, supercapacitors play a crucial role, relieving batteries from peak power demands, enhancing system responsiveness, and extending battery life through effective energy recovery during deceleration phases.

System Response Analysis

Supercapacitor Current Dynamics

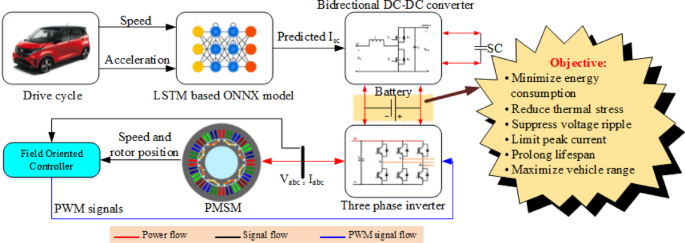

Figures illustrate the reference and actual supercapacitor (SC) current profiles during the EUDC. The reference current, generated via a Long Short-Term Memory (LSTM) model, represents the ideal assistance expected from the SC, while the actual current reflects its real-time response through a bidirectional converter. During phases of significant acceleration (e.g., at 60, 200, 284, and 344 seconds), the SC discharges actively, providing up to 16.6 A to meet instantaneous load demands, demonstrating its pivotal role in alleviating battery current stress and enhancing system responsiveness.

Conversely, during regenerative braking phases at around 122 and 347 seconds, the SC captures energy with peak currents of −20 A and −41.5 A, respectively. The close alignment of reference and actual currents during these intervals signals effective energy recovery and power control.

Battery Current and Dynamics

Battery current profiles for both Battery Electric Vehicles (BEV) and Hybrid Battery Electric Vehicles (HBEV) reveal significant insights. In acceleration phases, the BEV experiences steep current peaks (up to 82.7 A), while the HBEV enjoys reductions in peak currents (maximum 65.1 A) by 21.3% to 34%. These peaks indicate the SC’s role in managing transient load demands and reducing battery stress during critical acceleration phases.

During regenerative braking, the BEV registers deeper negative spikes (−75 A), whereas the HBEV experiences moderated values (−36 A). This highlights the SC’s efficiency in absorbing significant amounts of braking energy, which in turn helps to reduce harsh current flows into the battery, thus protecting its operational integrity.

Thermal Performance Comparisons

The battery temperature profiles for both configurations under the EUDC were examined to further understand thermal dynamics. Figure analyses reveal that as the BEV battery temperature rises sharply (302.2 K), particularly during high power demands, the HBEV configuration, aided by the SC, sustains a lower peak temperature of 300.8 K. This moderate temperature difference (approximately 1.4 K) plays a crucial role in mitigating thermal degradation and reduces the risk of thermal runaway during sustained operation.

Moreover, the I²R losses directly correlate with the difference in current behavior between the configurations. The HBEV, with SC support, maintains a more stable thermal profile, enhancing durability over time.

Voltage Profiles and Analysis

A comprehensive analysis of the voltage profiles also sheds light on the electrical performance during the EUDC. The BEV experiences more pronounced voltage drops under transient loads, dropping from 346.7 V to significantly lower values, whereas the HBEV maintains higher voltage levels due to the SC’s support. This leads to reduced voltage ripple, quantifying a 1.59% improvement in the HBEV configuration. Such stabilization contributes to optimizing battery life and enhancing overall system efficiencies.

Power Demand Dynamics

Both configurations exhibited differences in power demands throughout the EUDC cycle. During peak acceleration at around 334.7 seconds, the BEV records a demand of 27.92 kW, while the HBEV limits its requirement to 22.49 kW—an 18.1% reduction. This pattern continues into the regenerative phases, evidencing the SC’s vital contribution in offloading the battery during high-demand transients.

Energy Consumption Insights

Energy consumption trajectories reveal that the total energy consumed by the BEV is 547.5 Wh, while the HBEV registers 516 Wh—a net reduction of 31.5 Wh (5.75%). This highlights the SC’s effective role in handling transient power demands and optimizing energy flow without compromising performance.

Comparative Analysis under IM240 Drive Cycle

Moving beyond the EUDC, the IM240 drive cycle showcases similar performance metrics, underscoring the relevance of transient management in urban and highway settings. The reference and actual current profiles for the SC closely align, reflecting robust control and efficient handling of transient power requirements.

In this cycle, peak currents in the BEV identified during acceleration phases are significantly higher than those in the HBEV. For example, at 160 seconds, the HBEV’s peak battery current is recorded at 34.3 A compared to the BEV’s 51.59 A—demonstrating a 33.5% mitigation due to SC assistance.

Overall, the HBEV’s performance under the IM240 cycle corroborates earlier findings from the EUDC, consistently exhibiting enhancements in current stability, thermal performance, and energy efficiency.

Performance Metrics Summary

The comparative performance metrics, summarized comprehensively in tabular form, illustrate the clear advantages afforded by integrating supercapacitors into the hybrid battery configurations. From reduced peak currents and lower RMS currents to minimized battery temperature fluctuations, the HBEV outperforms the conventional BEV across various operational scenarios.

This detailed analysis provides a salient preview of how the integration of supercapacitors can enhance the performance and longevity of electric vehicle powertrains, advancing the sustainability and efficiency goals vital to the future of automotive design.