Unearthing the Superiority of HEA05 Fe35Ni29Co21Al12Ta3 Alloys

Introduction to Advanced High-Entropy Alloys

High-entropy alloys (HEAs) are revolutionizing materials science, particularly in tuning mechanical properties. The HEA05 Fe35Ni29Co21Al12Ta3 alloys stand out due to their unique dual precipitate microstructure. This composition consists of coherent L12 nanoprecipitates and incoherent B2 micro-particles embedded within a face-centered cubic (FCC) matrix, dramatically enhancing the material’s mechanical performance.

Mechanical Properties That Astound

The HEA05 alloy impressively showcases a yield strength ((\sigma_y)) of approximately 1.75 GPa, which is six times that of the base alloy A0, increasing from about 300 MPa to 500 MPa with just 3 at. % Ta, and reaching around 800 MPa with 12 at. % Al. While the latter two variations lead to a decrease in ductility, HEA05 excels with a uniform elongation ((\varepsilon_u)) of 25% and a drastically improved work hardening rate (WHR). The WHR of HEA05 consistently exceeds 2 GPa, marking a significant milestone in alloy design.

The Comparison Game

For context, we compared HEA05 with other alloys having different compositions. Two additional alloys were prepared: Fe35Ni24Co28Al11Ta2 and Fe35Ni24Co27Al11.5Ta2.5, which exhibited lower (σ_y) values and higher ductility. The systematic array of tensile stress-strain curves revealed the remarkable tunability of HEA05, demonstrating an impressive range of performance from 1.5 GPa to 1.95 GPa across various processing conditions.

The graphical representation in Fig. 3d and e highlights the positioning of HEA05 within the strength-ductility landscape, showcasing its dominance over previous alloy iterations.

Unpacking the Microstructure

At the heart of HEA05’s superior mechanical properties is its heterogeneous microstructure, rich in dual precipitates. The coherent L12 nanoprecipitates and B2 micro-particles form a robust framework that enhances yield strength through mechanisms of dislocation entrapment and strain hardening. The precipitate volume fractions reached unprecedented levels — 67% for L12 and 15% for B2, setting a new benchmark in alloy design.

The increased yield strength can be attributed to several factors:

- Coherent Strengthening: The interaction between dislocations and the L12 precipitates incurs a cost due to the creation of antiphase boundaries (APB), specifically heightened in Ta-alloyed L12 variants.

- Incoherent Interface Impact: The B2 micro-particles serve as strong barriers against slip transmission, effectively trapping dislocations and contributing to the overall strength.

High Work Hardening Capabilities

What truly sets HEA05 apart is its outstanding work hardening capability. As evidenced by transmission electron microscope (TEM) analyses, dislocation densities evolve significantly throughout the tensile testing phases. The occurrence of geometrically necessary dislocations (GNDs) accelerates strain hardening, leading to tensile elongation that exceeds expectations.

At strains between 5% and 20%, the density of GNDs heightened, showcasing interactions between the L12 and B2 phases that facilitate unique deformation mechanisms. The findings revealed that instead of failing, B2 particles demonstrated ductile behavior and took on significant roles in strain hardening—something traditional B2 phases struggled with.

The Role of Enhanced Ductility

An impressive aspect of HEA05 is the interaction between its precipitate phases, allowing for cooperative deformation rather than fracture. High densities of dislocations lead to better ductility, setting it apart from older HEA designs and traditional steels. The alloy does not simply resist failure; it maintains a ductile character under high strain, making it suitable for various demanding applications.

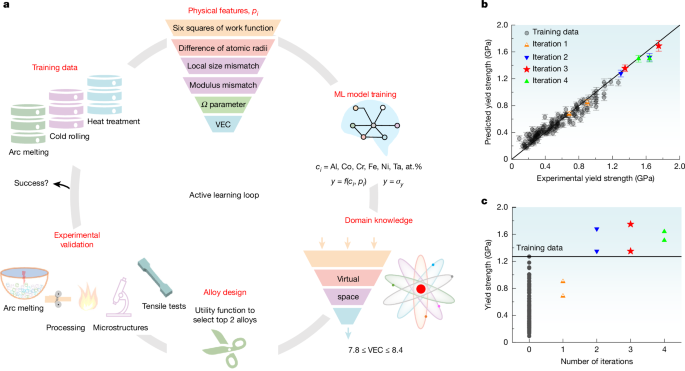

Tailoring Alloys through Machine Learning

The development of HEA05 was driven not just by metallurgical intuition but also by machine learning techniques that enabled rapid exploration of multi-element compositions. This approach allowed for a versatile design that embraced heavy alloying while optimizing for strength and ductility, showcasing a path forward for advanced material science.

Future Directions in Alloy Design

HEA05 sets a high bar in mechanical properties while maintaining the versatility and practical applicability necessary for complex engineering uses. The innovative strategies explored in this alloy’s design offer hopeful pathways for advancing other alloy systems where strength and ductility are critical.

The world of materials science is on the brink of transformative changes ushered in by advanced high-entropy alloys like HEA05. By effectively combining multiple phases and leveraging their interactions, researchers are pushing the boundaries of what’s feasible with metallic materials, promising exciting developments on the horizon.