As Advances in CNC Swiss Machining and Customized Components Address the Fundamental Physical Realities of Advanced Automation

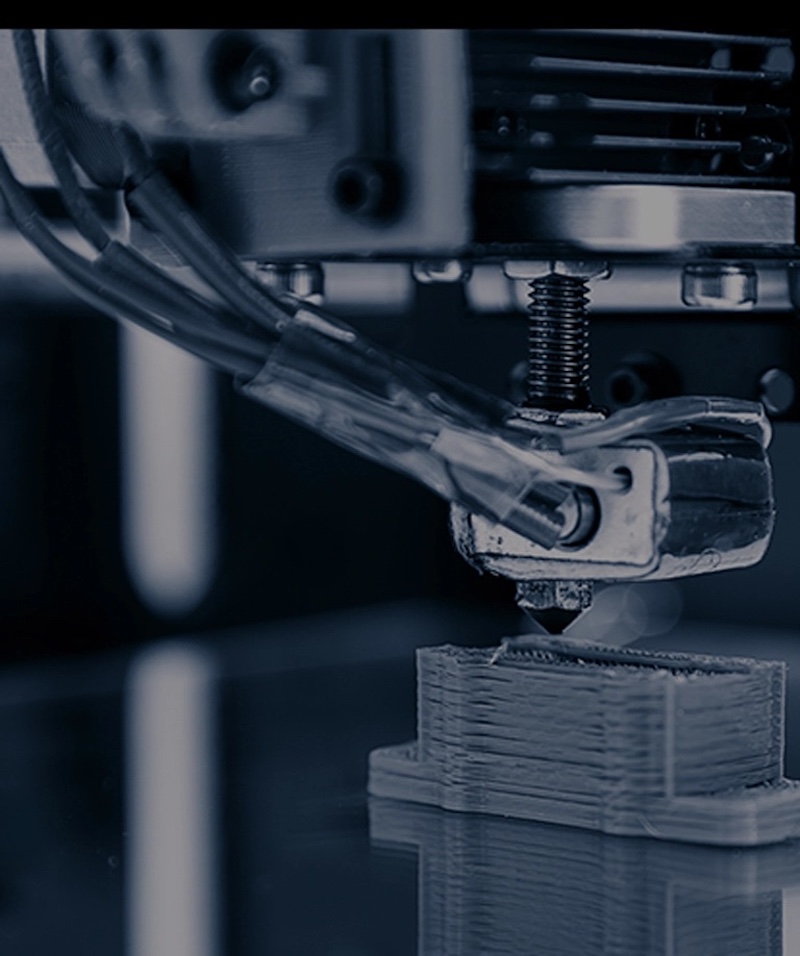

The overwhelming headlines in robotics often revolve around artificial intelligence, machine learning, and innovative software concepts. However, at the heart of these advancements lie precise, physical machines that execute digital instructions with predictability and reliability. As robotics evolves from rigid industrial arms to collaborative partners, the transformation in technology begins with the parts—an evolution deeply rooted in precision machining.

The Precision Core: CNC Swiss Machining for Robotic Actuation

Swiss machining, known for its precision, traces its origins back to the craft of watchmaking. It’s here that the need for small, intricately crafted components became paramount. At the heart of a Swiss-type lathe is a guide bushing, which helps reduce tool pressure and vibration, enabling the creation of high-performance, long, narrow, and complex parts that modern robotics require.

1. High-Performance Actuators

One of the greatest challenges in robotics is developing compact actuators with intricate internal geometries while maintaining power and density. To meet micron-level tolerances essential for smooth operations, CNC Swiss screw machining emerges as the only viable manufacturing solution. The precision in producing components like shafts and sensor housings ensures that robotic systems function seamlessly across their full range of motion.

2. Miniaturized Force Transmission

Precision reduction systems, such as harmonic drives, depend on exceptionally precise splines and gear profiles. Any variability can lead to errors, making CNC Swiss machining crucial. By ensuring each interface fits perfectly, manufacturers can achieve a zero-backlash operation, vital for different robotic applications ranging from semiconductor fabrication to surgical robots.

3. Sensor Positioning

Robotic arms are equipped with an array of sophisticated sensors, each requiring precise mounting features and bore alignment. CNC Swiss lathe machining’s ability to produce components that reduce misalignment issues ensures that input data for positioning remains accurate—a crucial element for effective robotic operation.

The Automated Body: Specialized Machining of Structural and Effector Components

While CNC Swiss machining plays a vital role in internal accuracy, general CNC machining equipment is indispensable for the overall structure and functionalities of robots.

Linear Motion Systems

Precision parts, such as ball screw nut housings and rail mounting blocks, must meet strict performance standards. These components require extraordinary flatness, parallelism, and bore accuracy to prevent binding and ensure smooth motion over millions of cycles—anything less could jeopardize operational reliability.

Advanced End Effectors

An end effector connects a robot to its workspace. Manufacturing an effective end effector involves several complex capabilities: creating lightweight yet structurally rigid components, precision machining for gripping jaws, and finishing internal passages for pneumatics and electrical pathways. This often involves advanced 5-axis milling and turning processes to meet the stringent demands for accuracy and functionality.

Mobile Robotics Components

In the realm of mobile robotics, reducing size and power consumption is crucial. Manufacturers are focusing on lightweight, high-strength materials like magnesium and aluminum alloys. This shift facilitates enhanced performance while maintaining structural integrity, making advancements in robotics more viable and reliable.

Manufacturing Foundations: Quality Means Quality

Creating components for automation transcends basic machining; it requires a commitment to quality and an understanding of dynamic loads in end-use scenarios.

Material Science

Careful selection and machining of materials—like 7075-T6 aluminum for strength or 4140 pre-hardened steel for wear resistance—are essential. The manufacturing process must prevent excessive heat and stress that can alter material properties, ultimately impacting performance.

Metrology and Traceability

Metrology is critical, with the use of Coordinate Measuring Machines (CMMs) and surface finish analyzers becoming standard. For certain actuator components where criticality demands, complete traceability from raw materials to completed parts is vital for quality assurance and effective root-cause analysis.

Design Partnership

Engaging manufacturers early in the design process can yield invaluable insights into Design for Manufacturability (DFM). Such collaboration not only enhances robustness but also reduces assembly issues and costs, ensuring that performance remains uncompromised.

The Future of Robotics

The trajectory of robotics points toward an increasingly autonomous and capable future. However, this evolution relies heavily on improving the physical hardware within these machines. CNC Swiss machining and specialized automation parts machining form the backbone of this progression, turning sophisticated algorithms into tangible, operational capabilities.

By collaborating with adept manufacturers across these disciplines, companies in the robotics sector can craft not only intelligent robots but also machines that are durable, reliable, and equipped to meet the rigors of tomorrow’s demands.