The Future of Robotic Physicochemical Sensing: A Control-Driven Paradigm Shift

The intersection of robotics and physicochemical sensing is rapidly evolving, necessitating a fundamental change in how we approach system design. Instead of merely innovating materials, the focus is now on crafting control-driven architectures that integrate sensory inputs with robotic behavior. This shift not only enhances the capabilities of robotic systems but also allows them to interact intelligently with their environments.

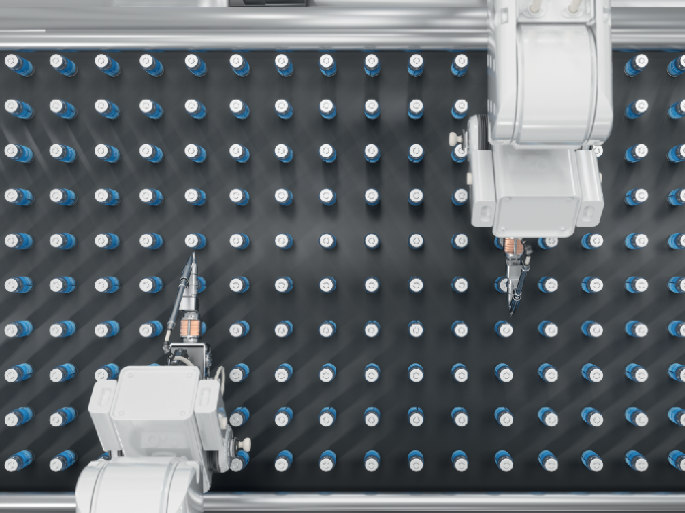

Emerging Technologies: Printed Multimodal E-Skins

At the forefront of this paradigm shift are innovative platforms, such as fully printed multimodal e-skins. These sophisticated devices are engineered to transduce, process, and respond to a variety of physicochemical signals in real time—temperature, pressure, strain, and hazardous compounds being just a few examples. Achieving such functionality necessitates the development of closed-loop control architectures. With these systems, sensory inputs actively modulate robotic actions through well-defined feedback pathways, leading to more responsive and adaptive interactions with the environment.

The Role of Sensor Fusion and Signal Conditioning

A core component of these advanced robotic systems is the sensor fusion and signal conditioning pipeline. This technology synchronizes multiple types of data, including tactile, thermal, electrophysiological, and electrochemical signals, into a coherent framework. This real-time processing allows robotic systems to execute complex actions, like haptic feedback or electrostimulation, enhancing user experience and system reliability. By decoupling chemical recognition from material-dependent transduction, these systems gain a crucial layer of reconfigurability. This means they can adapt flexibly to varying detection scenarios, broadening their applicability across different fields.

Real-Time Operation: Key Process Control Strategies

Effective real-time operation hinges on strategic process controls. Hierarchical signal processing plays a vital role, integrating low-level analog conditioning with higher-level artificial intelligence (AI) inference to ensure robust data interpretation. This multi-tiered approach allows for the simultaneous analysis of diverse signals—from electrophysiological to tactile, thermal, and chemical—leading to improved detection accuracy and comprehensive situational awareness.

Moreover, dynamic calibration and drift compensation techniques are crucial for ensuring long-term stability. These methods automatically adjust systems for environmental variations, ensuring consistent performance. Event-triggered actuation further enhances adaptability; for instance, robotic systems can adjust tactile feedback, stimulation, or mechanical adjustments based on the detected physicochemical changes in real time.

Aligning with Chemical Process Systems Engineering

The principles underpinning these advanced robotic systems are closely related to concepts in chemical process systems engineering, particularly in the realms of real-time feedback control, adaptive estimation, and fault tolerance. In this framework, robotic architectures—whether they are rigid, soft, wearable, or implantable—are reimagined.

Future advancements will largely depend on the convergence of soft bioelectronics, embedded intelligence, and control theory. This fusion will pave the way for autonomous sensing platforms capable of functioning within complex and dynamic environments. By implementing real-time control strategies, these systems will dynamically adjust sensing and actuation parameters in response to variable biosignals, ensuring optimal performance.

Emphasizing Robustness and Reliability

Adaptive estimation techniques will play a critical role in countering drift, degradation, and biological variability, ensuring that robotic systems can maintain their effectiveness over time. Furthermore, the incorporation of fault-tolerant designs, including redundancy and anomaly detection, will bolster operational resilience. By ensuring that these systems can continue functioning reliably even in the face of unexpected challenges, we move closer to developing intelligent, self-regulating robotic systems specifically suited for long-term, autonomous physicochemical monitoring and responsive intervention.

The Path Forward

As we forge ahead in the development of robotic systems integrated with physicochemical sensing capabilities, the importance of a control-driven paradigm cannot be overstated. The integration of advanced technologies and methodologies will allow for the creation of systems that not only sense but also act—adapting intelligently to their surroundings in real time. This evolution holds promise for diverse applications, from healthcare to environmental monitoring, opening a realm of possibilities that were once confined to the realm of science fiction. By focusing on intelligent design and adaptive control strategies, we stand on the brink of a new era in robotics—one that is responsive, versatile, and profoundly integrated with the complexities of the physical world.