A Hybrid Approach to Anomaly Detection in Furnace Monitoring

In modern manufacturing, the need for continuous monitoring and optimization of processes is essential, especially in high-stakes environments like foundries and steel mills where furnaces operate at extreme temperatures. To address the complexities of furnace monitoring, a proposed anomaly detection methodology seamlessly blends machine learning with traditional computer vision techniques. This hybrid approach unfolds across three processing phases, as illustrated in the accompanying overview diagram.

Phase 1: Joint Flame Semantic Segmentation and Furnace Keypoint Detection

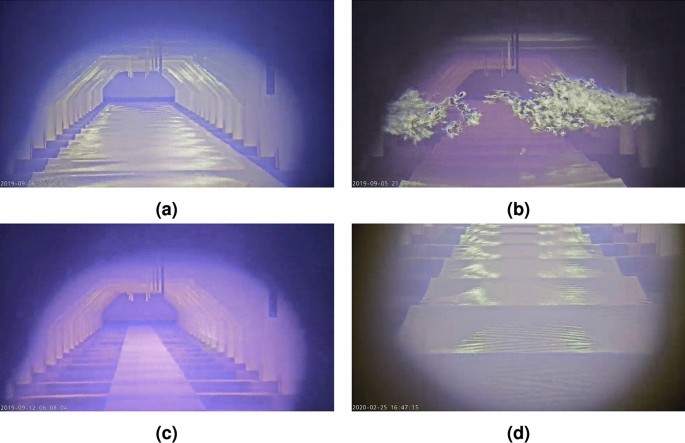

The first phase utilizes a deep learning model to analyze thermal camera images. This model excels in detecting and segmenting flames, as well as pinpointing critical key points within the furnace. The challenges encountered in traditional computer vision, such as flame reflections, noise, and varying exposures, necessitate the adoption of a deep learning strategy.

Model Architecture

At the heart of this approach is a specially designed architecture that employs a pretrained ResNet18 encoder integrated with a U-Net style decoder. ResNet18 was chosen for its efficiency in balancing performance with computational requirements, making it suitable for real-time applications. The architecture includes two output heads: one for flame segmentation and another for furnace keypoint detection.

The segmentation head interpolates the decoder’s output to match the input image resolution, while the keypoint detection head predicts heatmaps for 12 keypoints, enabling higher accuracy through Gaussian peaks. This dual-task setup facilitates effective learning during training.

Multitask Loss Function

Training the model requires a multifaceted loss function that amalgamates the errors from both tasks. It consists of a weighted sum of the Cross-Entropy loss and Jaccard loss for flame segmentation, and a Weighted Mean Squared Error (WMSE) for keypoint detection. This custom loss function enhances the model’s focus on keypoint locations, ultimately leading to improved stability and accuracy.

Phase 2: Flame Quantification per Burner Region

Once the flames and keypoints are detected, the next phase revolves around processing this information to quantify flames in three distinct furnace regions: the front, middle, and back. This quantification allows for a more nuanced analysis of flame behavior.

Inferencing Missing Keypoints

Despite advanced detection methods, challenges persist, such as poor image quality hindering keypoint predictions. The methodology incorporates rule-based checks to infer missing keypoints based on spatial relations to known points. For instance, if certain keypoints go unpredicted, the model can estimate their positions based on adjacent keypoints’ coordinates.

Constructing Furnace Region Masks

With the keypoints established, three masks corresponding to the burner regions are constructed. These masks utilize the spatial relations between keypoints, adapting dynamically to the available data. Fall-back procedures are in place for situations where certain keypoints may not be available, ensuring that the quantification remains robust even under less-than-ideal conditions.

Splitting the Flame Mask

Since the model outputs a single mask for all flames, an additional step is required to segment these into individual flames. Utilizing the Watershed algorithm, which treats intensity values as a topographical map, the methodology effectively identifies distinct flame locations, thus ensuring accurate assignments to their respective regions.

Phase 3: Anomaly Detection Per Burner Region

The final phase leverages the quantified data from the second phase to execute anomaly detection using a lightweight, interpretable machine learning model.

Decision Stump Classification

To identify anomalies in each burner region, decision stumps are employed, which are decision trees characterized by a single split. This choice is strategic, providing rapid and interpretable classifications directly correlating to flame areas.

Training Process

Training involves leveraging labeled frames to define anomaly states for each burner region. By constructing decision stumps tailored for each region, the model capitalizes on the distinct characteristics and behaviors of flames in those areas. The relationship between relative flame areas and anomaly states is striking, allowing accurate predictions even in varying operational conditions.

This innovative methodology presents an effective solution for monitoring furnace operations, combining advanced machine learning with time-tested computer vision techniques. Through its three-phase processing pipeline, the system not only enhances operational transparency but also facilitates proactive maintenance and issue resolution, ensuring that high-temperature tasks are conducted safely and efficiently.