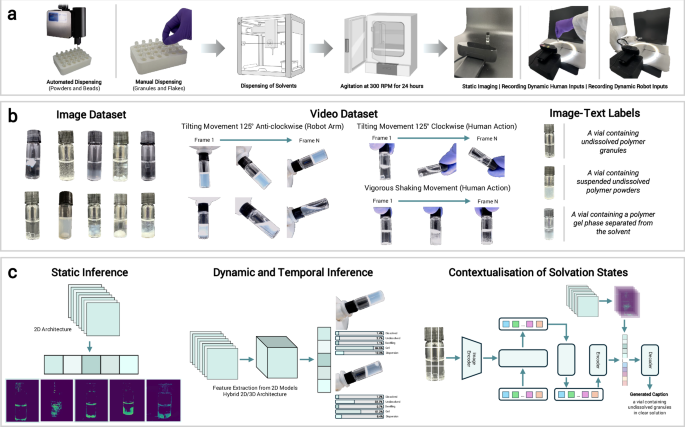

Workflow for Generating Polymer Solvation Dataset

Comprehensive Data Generation

To train the Variational Autoencoder (VA), we kicked off a large-scale data generation campaign that involved meticulously testing 200 unique homo- and co-polymers against 36 solvents at four distinct temperatures: 4°C, 25°C, 50°C, and 75°C. This multifaceted approach aimed to thoroughly capture the diverse interactions between polymers and solvents, enlightening us on behaviors such as dissolution, swelling, and dispersion under laboratory conditions that mirror real-world scenarios.

Semi-Automated Workflow

To ensure efficiency and consistency throughout our data generation, we crafted a semi-automated workflow that cleverly blended robotic and manual techniques. We utilized a ChemSpeed (SWILE) robotic system to dispense polymers into 1.5 mL clear glass vials. This robotic system, equipped with precise glass dispensing tools, allowed for the rapid dosing of powdered polymers. For polymer formats like flakes or granules—which were incompatible with the robotic system—manual dosing was necessary.

Meanwhile, solvents were measured and dispensed into 25 mL clear glass vials via an OpenTrons OT-2 liquid handling robot. This setup ensured accurate and reproducible measurements. To house these vials, we designed custom racks using 3D printing with acrylonitrile butadiene styrene (ABS), selected for its chemical durability against typical solvents.

Experimental Preparation

Each polymer-solvent combination was prepared at a 2.5 wt/vol% concentration, optimizing visibility for solvation behaviors. Following solvent addition, the vials were placed in a Corning LSE 71 L shaking incubator. Here, they were agitated at 300 RPM for 24 hours under carefully controlled temperatures (±0.5°C). This ensured the dataset mirrored typical lab environments, negating the need for specialized lighting setups during photography.

Diverse Polymer and Solvent Selection

To enrich the diversity within our dataset, we explored a wide array of polymer types, including polystyrene, polymethyl methacrylate, polyacrylic acids, polyvinyl chloride, polyvinyl acetate, polyvinylpyrrolidone, and polyvinyl alcohol. The polymers appeared in various physical forms such as powders, granules, and flakes. We also tested these polymers against a spectrum of industrial solvents—including alcohols, ketones, and hydrocarbons—to encapsulate a broad range of solvation behaviors.

Image Capture and Enhancement

Images were acquired using a diverse array of equipment, like a Logitech C920 webcam, iPhone 13, and iPhone 14 Pro Max. Captured in .jpg format with resolutions of 3024 × 4032 pixels, images were taken in controlled conditions to ensure consistency. We employed either a portable photography chamber or a benchtop platform featuring a black background to enhance contrast.

Photos underwent meticulous adjustments in contrast and brightness to counterbalance the variability of lighting. Diffused lighting techniques helped achieve uniform illumination, thereby preserving key details necessary for reliable classification.

Capturing Dynamic Behaviors

Videos, captured solely with the Logitech C920 webcam at a resolution of 1920 × 1080, were sampled at 30 frames per second, to monitor dynamic solvation behaviors like gel formation and swelling. Two methodologies were employed: manual handling by researchers, who agitated and tilted the vials to mirror standard laboratory practices, and a robotic arm that executed standard movements. This dual approach resulted in a comprehensive dataset that not only captured static behaviors but also the dynamic interplay of solvation states.

Comprehensive Dataset Creation

Ultimately, this rigorous workflow generated a rich dataset of polymer-solvent interactions, showcasing both static (image-based) and dynamic (video-based) behaviors. This dataset served as the backbone for training the VA’s static inference module (2D-CNN) and dynamic inference module (3D-CNN), enabling an adept classification and interpretation of polymer-solvent behaviors.

Static Inference Module

The static inference module was crafted to classify polymer-solvent interactions through high-resolution images taken in controlled conditions. From a total dataset of 13,663 images, 4,875 were manually categorized into five groups: dissolved, undissolved, swelling, gel, and dispersion. A balanced representation within these categories was achieved through a selective sampling strategy, ensuring diverse solvation behaviors and minimizing potential model bias.

In detail, the dissolved class comprised 925 images of clear liquids with no visible solid particles. The undissolved class contained 1,070 images displaying solid polymer structures. The swelling class included 960 images of polymers that changed physically due to partial solvation, while the gel class featured 861 images of semi-solid materials. Finally, the dispersion class encompassed 1,059 images of cloudy liquids with finely dispersed polymer particles.

Model Architecture and Training

The model architecture for the 2D-CNN was designed for effective classification. Input images were resized to 224 × 224 pixels, and the architecture consisted of three convolutional layers, equipped with filtering and pooling layers for maximal feature extraction. Incorporation of a fully connected layer linked to a Dropout layer helped combat overfitting, culminating in a softmax output layer to yield classification results.

In addition, we fine-tuned several pre-trained models (e.g., VGG16, InceptionV3, ResNet50, and DenseNet121) for comparative performance analysis. This process preserved valuable feature representations while adapting the models to the polymer-solvent classification task.

Dynamic Inference Module

Moving forward, the dynamic inference module was developed to address limitations in static image analysis. Traditional static images often neglect transient phenomena such as swelling and gelation, which need motion for effective observation. Thus, this dynamic module processes video inputs, allowing us to consider temporal changes in polymer behaviors.

The 3D-CNN trained on a dataset of 5,053 videos, incorporating both robotic and manual handling methods. Uniformity in video framing ensured the vials were consistently centered, while the inclusion of natural variability from manual techniques improved generalizability in real-world applications.

Through the architecture of the 3D-CNN, which comprised multiple convolutional layers and dropout rates, we effectively learned to discern dynamic behaviors across video sequences.

Contextualisation Module

The contextualisation module utilizes a vision-language model for enhanced interpretability, generating descriptive captions for images related to polymer-solvent interactions. Performing domain adaptation on the BLIP-2 model using a custom dataset, we prepared it for generating nuanced image captions.

Training involved various configurations, meticulously balancing computational efficiency with the capacity to articulate domain-specific details. Our efforts were directed toward capturing the essence of solvation behaviors in sufficient detail to support the overarching research objectives.

Understanding Polymer Solvation Behaviors

Recognizing the diverse physical forms that polymers can take—ranging from granules to beads—is pivotal for assessing solvation behaviors. In this study, we categorized polymer solvation behaviors into five primary classes: dissolved, undissolved, swelling, gel, and dispersion.

Dissolved behavior describes polymers fully integrated within the solvent, yielding a uniform solution. In contrast, undissolved states maintain the polymers’ original form, clearly showcasing phase separation. Swelling indicates polymers partially interacting with the solvent, leading to observable changes in structure. Gel formation represents a thicker, viscous state, showcasing a different set of interaction dynamics, while dispersion describes systems where solid particles are suspended, often exhibiting cloudiness and turbidity due to variable particle sizes.

Through this structured exploration, we illustrate the intricate interactions between various polymers and solvents, laying the groundwork for future research and applications in polymer science.