Unveiling the Secrets of Chalcogenide Glass Dataset and Graph Classification

Understanding Chalcogenide Glasses

Chalcogenide glasses are intriguing materials comprised primarily of chalcogen elements—sulfur (S), selenium (Se), and tellurium (Te)—while deliberately omitting other elements like oxygen and certain metals such as silver and gold. This unique composition lends these glasses exceptional properties, positioning them as crucial players in electronic, optical, and photonic applications. To better comprehend these materials, researchers have amassed extensive data on their properties, particularly through the SciGlass database.

The Chalcogenide Dataset

The dataset under discussion boasts a diverse set of 556 glasses, comprising:

- 355 glasses with sulfur (S)

- 350 with selenium (Se)

- 26 with tellurium (Te)

- 339 containing germanium (Ge)

This wealth of information allows researchers to draw meaningful conclusions and design new materials.

Statistical Insights

In an exploration of the dataset, statistical samples reveal critical output properties:

- Glass Transition Temperatures (Tg): This ranges from 298 K (minimum) to 763 K (maximum).

- Coefficient of Thermal Expansion (CTE): Observed values span from −4.86 to −4.18.

- Refractive Index: The refractive index notably varies between 2.09 and 3.05.

Though this dataset may be smaller than those seen in other studies, it remains robust enough for model development and evaluation.

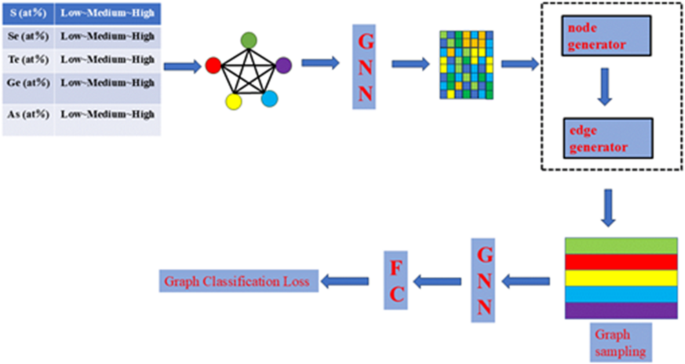

Transforming Data for Graph Representation

The study also investigated the data’s potential through graph-based representation. Four graph-structured datasets were created, drawn from 10%, 20%, 50%, and 100% of labeled data. This graphical approach not only enriches model development but also facilitates a more nuanced evaluation of the underlying relationships between different glass compositions.

Each dataset was meticulously classified into low, medium, and high ranges, based on both the molar percentages of the input components and their output attributes. This classification serves as an essential foundation for the subsequent modeling stages.

Material Examples in Prediction

One of the captivating aspects of this study lies in predicting material properties based on elemental composition. The process begins by transforming quantitative data—such as ratios of Ge, As, Se, Te, and S—into qualitative classifications: high, medium, or low. This transformation is essential for constructing a structured graph representation. Each material is then modeled as a graph, with nodes and edges characterizing the connections among elemental features.

Real-World Examples

-

As₄₀Se₆₀: In this composition, arsenic (As) is designated as high and selenium (Se) as low, among other classifications. The model predicts corresponding property labels, which can be mapped to certain ranges of material properties.

-

Ge₃₀As₁₃Se₅₇: This glass presents a classification where Ge is high, As is medium, and Se is high. The model again predicts corresponding output property labels, demonstrating the predictive capability of the model.

- Ge₂₅As₂₀Se₂₅Te₃₀: Classifications here depict Ge and As as high, while Se and Te hold medium and high labels, respectively. The model continues to provide insight into potential property predictions based on elemental input.

Building and Training the Model

Training the classification model involved replicating conditions from previous studies, specifically the GHNN framework. The model underwent 300 epochs of training, utilizing a batch size of 64 along with the Adam optimizer at a learning rate of 0.01. This systematic approach of repeated experiments further bolstered the accuracy of the resulting model.

Evaluation Metrics: A Deep Dive into Model Reliability

A reliable model hinges on effective evaluation indicators—accuracy (ACC), recall, and the F1 score—each providing essential insights into performance.

-

Accuracy (ACC): This computed metric reflects the proportion of correctly identified outcomes. The mathematical representation underlines how true positives, true negatives, false positives, and false negatives contribute to the overall accuracy.

-

Recall: As the capacity to identify all positive classes, recall is crucial for evaluating how comprehensively the model discovers relevant material properties.

- F1 Score: Functioning as a harmonic average of precision and recall, this metric balances the two capacities, enhancing the interpretability of results related to model performance.

Analyzing Results: The Model’s Performance in Various Contexts

To assess the model’s robustness and generalizability, multiple sample sets (10%, 20%, 50%, and 100%) from the dataset were examined. This stratification aimed to provide insights into how data size influences model performance, including comprehensive comparisons with other prevailing graph classification methods in the literature.

Comparative Performance

The results reveal that the proposed model markedly outperformed its counterparts—DGCNN, DCNN, ECC, DGK, GCN, and others—especially in smaller datasets. For instance, with just 10% of the dataset, the model achieved an accuracy of 0.782, eclipsing the nearest competitor, GraphSAGE-GCN, at 0.723. As the dataset’s size increased to 100%, the model’s accuracy climbed to 0.846, showcasing its superior learning capacity.

Evaluating Recall and F1 Scores

From the recall metrics, the model maintained a strong performance across the dataset proportions, with notable improvements reflecting its ability to efficiently process and utilize labeled data. The F1 scores confirmed this trend, consistently positioning the proposed model ahead of the competition—especially against traditional graph embedding models such as DeepWalk, which notably lagged.

By methodically delving into the nuances of chalcogenide glasses’ properties and leveraging sophisticated graph-based learning, this research illustrates a pioneering pathway toward optimizing material design and applications across various scientific fields.