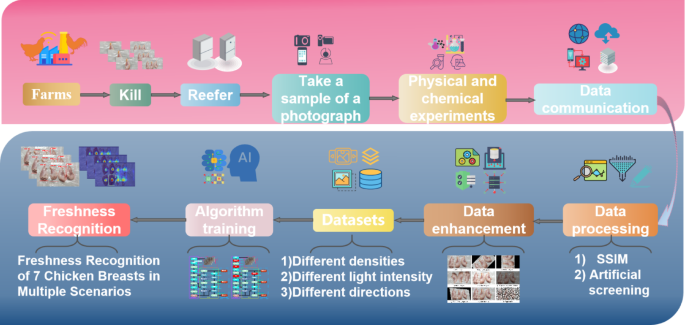

Preparation and Recognition Process for Chicken Breast Freshness

Understanding chicken breast freshness is critical for both food safety and quality assurance. This article delves into an intricate preparation and recognition process, which includes sourcing, sampling, classification, and data analysis.

Sourcing and Initial Procedures

The study examines broiler chickens obtained from Tiancheng Farm in Xuancheng City, Anhui Province. The entire process begins with the slaughtering of 144 healthy broiler chickens. This occurs in the early hours, between 8:10 and 10:30 AM. A team of five skilled butchers ensures that the process follows sanitary guidelines firmly established within an enclosed slaughterhouse.

Post-slaughter, the chicken breasts are promptly stored in a freezer at −20 °C, ensuring they remain uncontaminated until they reach the laboratory for further analysis.

Preparation of Chicken Breast Samples

Once in the lab, the fresh chicken breast samples undergo a meticulous seven-day video sampling session. This procedure involves using a fixed Logitech C920Pro camera and a mobile Huawei Mate20 Pro smartphone to capture images, ensuring high quality with a resolution of 1920 × 1080 pixels. The images are essential for visual recognition, setting the foundation for subsequent freshness assessments.

Classifying Freshness Levels

Following national standards, chicken breast freshness is categorized into seven levels based on various microbiological and chemical parameters:

- Fresh

- Second-fresh_1

- Second-fresh_2

- Second-fresh_3

- Carrion_1

- Carrion_2

- Carrion_3

These classifications depend on key metrics such as the Total Aerobic Count (TAC), coliform bacteria counts (ANC), and pH values.

Data Communication and Transmission

Collecting and processing the chicken breast images and relevant microbiological test samples require a robust data communication strategy. These resources are transmitted via networks, cloud servers, and routers to practitioners who are involved in further analysis.

Data Filtering and Augmentation

To enhance the dataset’s quality, high structural similarity (SSIM) metrics are applied to filter out highly similar and redundant chicken breast samples. Following this, data augmentation techniques come into play. Various methods enrich the dataset to include nuanced variations—different lighting conditions, angles, and density levels are configured, which ultimately enhance the robustness of the dataset for training the algorithm.

Training Algorithm Models

The culmination of these processes results in the training of multiple algorithm models aimed at non-destructive recognition of chicken breast freshness levels. Among these models, the YOLOv8n_CA_DSC3 emerges as the optimal choice, enabling accurate recognition across various circumstances.

Chicken Breast Image Sample Preparation Process

As previously outlined, TAC, ANC, and pH value remain pivotal indicators for grading chicken breast freshness. The procedure for inspecting image samples is methodical:

- Initially, 144 healthy chickens are humanely slaughtered, resulting in 288 pieces of fresh chicken breast.

- The samples undergo division into three groups—A, B, and C—each labeled accurately to facilitate tracking.

- Group A includes 112 samples, Group B has 96, and Group C comprises 80 pieces, all stored at −20 °C before gradually transitioning to 4 °C for further image collection and analysis.

The meticulous daily assessments unveil the intricate dynamics of poultry freshness, creating a continuous loop of data collection evident in the analyses and imagery documentation.

Freshness Classification Standards

Adhering to national guidelines, chicken breast freshness levels are classified into seven distinct segments based on biochemical metrics. Each freshness category correlates with specific parameters defining both microbial counts and pH values, thereby ensuring that the classification remains robust and standardized.

Key Metrics for Classifications

- The pH value for fresh samples lies between 5.5 and 6.2; this figure escalates in carrion samples, where readings might rise above 7.0.

- TAC and ANC counts indicate the microbial content, significantly increasing in carrion categories compared to fresh samples.

The examination of these metrics aids regulatory and quality control bodies in maintaining food safety standards.

Preprocessing and Enhancements of Data

Given the challenges of distinguishing close freshness levels, Structural Similarity Index (SSIM) is utilized to filter out redundant samples from collected images.

Data points are collected under varied conditions to bolster a practical dataset for training recognition algorithms. The ultimate objective is to prepare a robust set of 3820 valid sample images encapsulating all seven freshness levels.

Augmentation Techniques for Increased Robustness

The data undergo several augmentation techniques to enrich its diversity. Adjustments include altering brightness, introducing random noise, and performing rotational transformations. Such creative methods simulate real-world scenarios and enhance model robustness against varied recognition environments.

YOLOv8 Algorithm Model

Emerging from the YOLO family of models, YOLOv8 introduces various architectural enhancements aimed at improving detection accuracy while offering five distinct model variations. The depth and width of these networks scale with parameter counts and are optimized for practical applications in recognizing chicken breast freshness.

DCNv3 Module Optimization

The DCNv3 module—an enhancement to its predecessor, effectively contributes to feature extraction by harnessing long-range dependencies within images. By modifying convolutional neuron interactions, this model strives to provide insights into adaptive spatial aggregations crucial for the recognition task.

Integration of Channel Attention Mechanism

Introducing a Channel Attention (CA) mechanism allows for refined relationships among various channels, bolstering feature representation. This adjustment enables better localization of features within the datasets, amplifying learning efficiency alongside minimal computational overhead.

By focusing on diverse yet crucial aspects of chicken breast freshness in this systematically driven preparation and recognition process, food safety can be better ensured while enhancing quality control standards across the poultry industry.