“BD and Opentrons Join Forces to Advance Single-Cell Multiomics through Robotic Automation”

BD and Opentrons Join Forces to Advance Single-Cell Multiomics through Robotic Automation

Understanding Single-Cell Multiomics

Single-cell multiomics refers to the analysis of multiple biological processes (like gene expression and protein levels) within individual cells. This approach provides a comprehensive view of cellular functions, making it crucial for advancements in fields like oncology and immunology. The collaboration between BD (Becton, Dickinson and Company) and Opentrons Labworks aims to revolutionize this area, enabling faster and more reliable research outcomes.

The Business Impact of Automation

Automating laboratory processes promises significant benefits in research settings. BD and Opentrons’ collaboration will integrate robotic liquid-handling with BD’s single-cell multiomics instruments. This enhancement seeks to streamline experimental workflows, facilitating faster disease research and the development of new drugs. By enabling hands-free workflows, scientists can explore data with unprecedented speed and accuracy, ultimately leading to better healthcare solutions.

Key Components of the Collaboration

The core components of this partnership include:

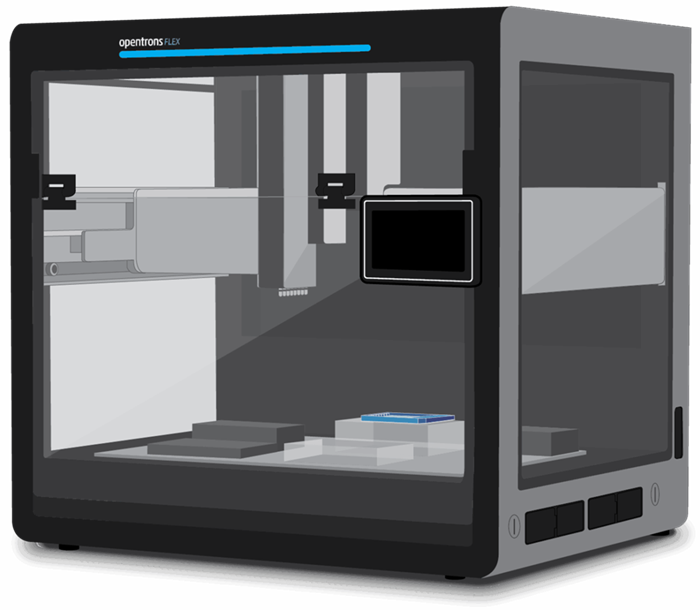

- Integration of Robotics: BD Rhapsody™ System will integrate with the Opentrons Flex® platform.

- Automation-Compatible Modules: Development of modules that automate critical experimental steps, particularly for next-generation sequencing library preparation and cell capture.

- Verified Protocols: Collaboratively designed protocols will allow labs to perform experiments with minimal manual intervention.

These elements not only simplify processes but also enhance reproducibility in research outcomes.

Step-by-Step Process for Implementation

The automation integration will unfold in several sequential steps:

- System Identification: Laboratories will identify their needs—such as optimizing cell sorting or sequencing.

- System Installation: Opentrons’ robotic systems will be implemented alongside the BD Rhapsody™ System.

- Protocol Development: Verified protocols tailored to specific experimental needs will be developed.

- Training: Lab personnel will receive training on the new automated systems and protocols to ensure effective usage.

- Experimentation: Researchers will conduct experiments utilizing newfound automated workflows.

- Data Analysis: Automated processes will allow for quick, uniform analysis of experimental data, enhancing insights and conclusions.

Each of these steps is critical for ensuring that automation translates into real-world efficiency and effectiveness in research settings.

Real-World Application: A Mini Case Study

Consider a laboratory focused on cancer research that aims to profile tumor microenvironments at the single-cell level. By integrating BD’s Rhapsody™ System with Opentrons’ robotic capabilities, the lab can automate the preparation of sequencing libraries. This not only accelerates the process, enabling researchers to analyze more samples in less time but also reduces human error during manual handling. The result: more reliable insights into tumor behavior and potential treatment pathways.

Common Pitfalls and How to Avoid Them

Despite the advantages of automation, there are common pitfalls. One major issue can be the complexity of integrating new technologies with existing systems. This can lead to disruptions in workflows, causing delays and frustration.

To avoid this, thorough planning is essential. Labs should perform a comprehensive needs assessment and engage in extensive training sessions for staff. Establishing a feedback loop between researchers and operational teams during the integration phase can also help identify issues early.

Tools and Metrics for Success

Incorporating automation in laboratories requires the right tools and metrics to measure success. Scientists often utilize tools like liquid handling robots and analytical software to optimize experiments. Metrics such as time taken for sample processing, error rates, and data reproducibility become critical indicators of a successful integration. Laboratories achieving high efficiency with a low error rate can expect better research outcomes, positioning them strategically in the competitive landscape.

Variations and Alternatives

While BD and Opentrons’ collaboration presents a powerful model, other options exist. For example, labs might consider manual processes or alternative automated systems from competitors. The trade-off usually lies in balance: manual processes offer more immediate control but are slower and less consistent, while other automated systems may not specialize in single-cell multiomics or may require full system replacements.

Choosing the right approach largely depends on the specific goals of the research and the existing systems in place.