Key Insights

- Innovative advancements in robotic arm design are transforming manufacturing landscapes.

- Integration with AI and machine learning enhances precision and adaptability.

- These technologies enable smaller businesses to automate previously labor-intensive processes.

- Robotic arms are increasingly utilized in dynamic environments, improving operational efficiency.

- Regulatory challenges and safety considerations remain critical as deployment scales up.

Revolutionizing Manufacturing with Next-Gen Robotic Arms

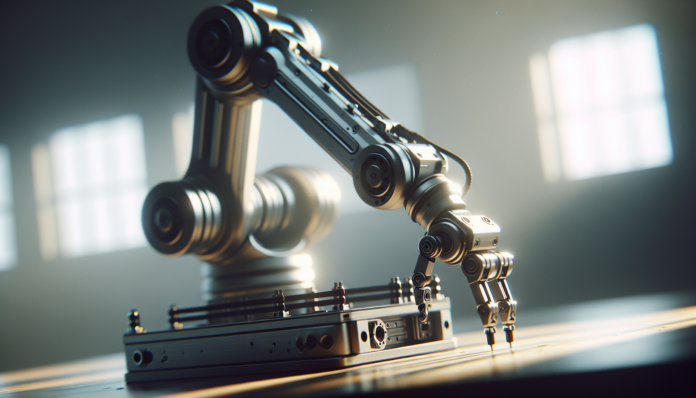

In the ever-evolving domain of robotics and automation, technological innovations continue to redefine industry standards, with a pronounced focus on enhancing productivity and efficiency. Advances in robot arms enhance automation and manufacturing efficiency, introducing capabilities that were previously inconceivable. These next-generation robotic systems are not only increasing output but also enabling businesses, especially small to mid-sized firms, to streamline operations and improve overall performance. A striking example of this trend can be observed in assembly line settings, where robotic arms are rapidly adopted to handle repetitive tasks, thereby replacing manual labor. As these advanced robotic technologies proliferate, understanding their implications is crucial for both industry leaders and operators alike.

Why This Matters

Technical Advances in Robotic Arm Design

The engineering behind modern robotic arms has progressed significantly, resulting in devices that are more efficient, versatile, and cost-effective. Today’s robotic arms incorporate advanced materials and components that allow for increased load capacities and faster motion profiles. This is crucial in manufacturing environments where precision and speed are paramount. Technologies such as torque sensing and high-resolution encoders enhance feedback mechanisms, allowing for real-time adjustments during operation. Such capabilities are particularly beneficial in environments where tasks vary frequently or where the robot must interact closely with human workers.

Real-World Applications in Diverse Industries

Robotic arms are being applied across diverse sectors including automotive, electronics, food processing, and healthcare. In the automotive industry, for example, robotic arms are employed for welding, painting, and assembly tasks, improving throughput while ensuring high-quality standards. Similarly, in electronics manufacturing, these robots can manage intricate assembly processes with extraordinary precision, reducing the potential for human error. Moreover, with specialized attachments being developed, robotic arms can also perform a range of functions from handling delicate components to packaging finished products.

Economic and Operational Implications

The adoption of robotic arms is not just about enhancing speed; it also presents significant economic advantages. Companies implementing these advanced systems often experience reduced labor costs and increased operational efficiency. According to various industry analyses, businesses that have automated their processes report a productivity increase of 20-50%. Automation through robotic arms can also mitigate risks such as workforce shortages, helping companies maintain consistent production levels. Furthermore, as small businesses embrace automation, they can remain competitive against larger enterprises, leveling the playing field in a fast-changing market.

Safety and Regulatory Considerations

As robotics in manufacturing gain traction, safety concerns and regulatory compliance become increasingly important. Robotic arms must be designed to minimize risks associated with human interaction. Safety features, such as emergency stop buttons and sensors that detect human presence, are becoming standard in many automated setups. Compliance with regulations set by organizations like the Occupational Safety and Health Administration (OSHA) is crucial to ensure safe operating environments. The integration of safety standards in robotic design not only protects human workers but also enhances overall workforce morale and acceptance of automation technologies.

Impact on Technical Builders and Non-Technical Operators

The integration of advanced robotic arms signals a shift that benefits both technical builders and non-technical operators. Developers and engineers are at the forefront, creating algorithms and software that make robots more intelligent and user-friendly. This shift is balanced by the need for operational personnel to adapt to new technology through training and skill development. Small business owners, creators, and even students can leverage these robotic innovations to automate routines or undertake projects that were previously unfeasible. This democratization of technology enables a broader spectrum of society to engage with advanced manufacturing processes.

Failure Modes and Risk Management

While robotic arms offer numerous advantages, they are not without their challenges and potential failure modes. Common issues include mechanical failures, software bugs, and safety incidents that may arise from improper programming or maintenance. The cost of downtime resulting from such failures can be substantial, highlighting the importance of robust maintenance practices and contingency planning. Additionally, as reliance on technology increases, the risk of cybersecurity threats also escalates. Ensuring the integrity of software and communication networks is critical to maintain operational continuity and protect sensitive data.

The Supply Chain and Ecosystem Impact

The evolution of robotic arms is also reshaping supply chains and industry ecosystems. As automation becomes more widespread, manufacturers must rethink their supply logistics to accommodate the capabilities and needs of robotic technology. This includes revising the procurement of necessary components and establishing new vendor relationships to ensure a steady supply of advanced robotics systems and parts. Moreover, software ecosystems that support robotic arm operations—ranging from programming interfaces to data analytics platforms—are also evolving. Such developments indicate a significant shift in how businesses approach both production and market competitiveness.

What Comes Next

- Monitor advancements in AI integrations for real-time adaptive learning in robotic operations.

- Watch for emerging regulatory frameworks that address the evolving landscape of automation safety.

- Look for small businesses adopting advanced robotic solutions to enhance efficiencies and reduce costs.

- Anticipate innovations in modular robotic designs that enable customizable applications across various industries.