Key Insights

- Robotics and automation are increasingly driving operational efficiency in industries like manufacturing and logistics.

- Collaborative robots (cobots) are enhancing human-robot interaction, making workplaces safer and more productive.

- Artificial intelligence integration is offering real-time data analysis, leading to smarter decision-making in automated systems.

- Supply chain optimization is being redefined through the adoption of autonomous vehicles and drones.

- Regulatory frameworks are evolving to address safety and operational standards for emerging robotic technologies.

Boosting Productivity: The Latest Innovations in Robotics and Automation

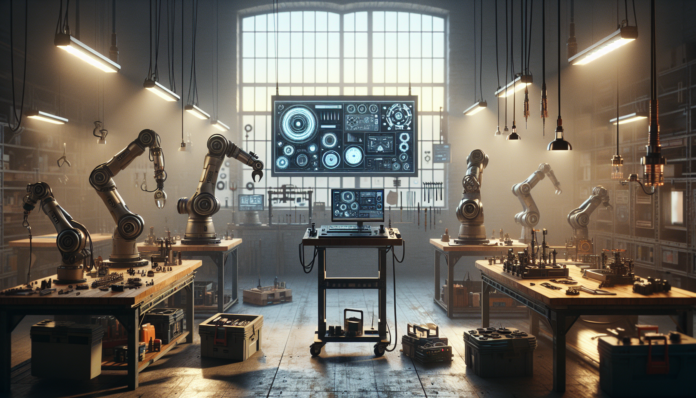

The landscape of industrial operations is undergoing a profound transformation due to rapid advancements in robotics and automation technologies. As companies strive for increased efficiency and reduced operational costs, they are turning to innovative solutions that leverage both robotics and AI. Recent advancements enable businesses to optimize processes in manufacturing, logistics, and other sectors. This theme is evident in the discussion on “Advancements in Robotics and Automation for Industry Efficiency,” where we explore how such technologies are enhancing productivity and altering the workforce dynamics. For instance, warehouse automation systems are now equipped with intelligent robots that can process orders faster and more accurately, reducing human error and lifting the burden on employees. However, while automation offers numerous benefits, it also presents challenges that businesses need to strategically navigate.

Why This Matters

The Technological Landscape

Recent innovations in robotics and automation have ushered in significant technological shifts across various industries. Autonomous robots, equipped with AI, can analyze their environment and make decisions in real-time, exemplifying a leap forward from traditional automation. These robots are designed for versatility and adaptability, allowing them to perform complex tasks. The integration of AI algorithms enables predictive maintenance, reducing downtime and enhancing operational fluidity. Additionally, Machine Learning (ML) capabilities allow for the continual refinement of these systems, learning from past performance to improve future outcomes.

This shift is not limited to isolated processes within a factory or warehouse. In many deployments, these technologies are interconnected through the Internet of Things (IoT), creating an ecosystem wherein data flows seamlessly between machines, operators, and management systems. This connectivity provides a holistic view of operations, enhancing efficiency at every stage of supply chain management.

Real-World Applications

Robotics and automation technologies are being deployed across various sectors with notable success. In manufacturing, collaborative robots, or cobots, are deployed alongside human workers, performing repetitive and physically demanding tasks. This enables workers to focus on more complex aspects of production, ultimately enhancing output quality and employee satisfaction. In logistics, automated guided vehicles (AGVs) streamline inventory management and facilitate product transport, allowing companies to respond swiftly to consumer demands.

Beyond traditional industries, innovative automated solutions have found their place in agriculture, healthcare, and even customer service. For example, drones are increasingly being used for agricultural monitoring and crop optimization, enabling farmers to make data-driven decisions that boost yield. In healthcare, robotic surgical systems enhance precision in operations, reducing recovery times and improving patient outcomes. The range of applications demonstrates the versatility and transformative potential of robotics and automation.

Economic and Operational Implications

The realignment of work processes brought on by robotics and automation presents profound economic implications. Cost savings from reduced labor and increased productivity can lead to higher profit margins, fueling reinvestment into further innovation. Furthermore, the fluctuation of labor markets due to automation leads to a shift in workforce skills, necessitating retraining and upskilling initiatives for employees. Transitioning into a world where robots handle routine tasks challenges the workforce to adapt by acquiring new competencies that complement automated solutions.

Operationally, the introduction of robotic systems often leads to alterations in workflow design. Companies that embrace this technology must reassess their organizational structures to accommodate new collaborative frameworks between human operators and machines. This integration can optimize resource allocation and enhance workplace efficiency, but it also requires clear communication and training initiatives to ensure that teams operate cohesively.

Safety and Regulatory Considerations

As robotics and automation proliferate, safety and regulatory compliance become paramount. Various international standards bodies are developing guidelines aimed at establishing safety protocols, ensuring that robotic systems operate securely within human environments. For instance, ISO standards for collaborative robots dictate specific safety measures to mitigate hazards during operation.

While these frameworks provide critical safety guidelines, the rapid pace of technological advancement continuously challenges existing regulations. Companies are often tasked with staying updated on compliance requirements that evolve alongside technological innovations. Furthermore, a lack of established regulations can lead to inconsistent safety practices, raising concerns about worker protection and public safety as more automated systems enter the market.

Connecting Developers with Non-Technical Operators

The convergence of advancements in robotics and automation is also fostering engagement between developers and non-technical operators. For developers, creating user-friendly interfaces and accessible programming tools is critical in ensuring that operators from various backgrounds can effectively utilize these technologies. This bridges the gap between sophisticated robotics and their application in everyday operations.

Non-technical operators, such as small business owners and homemakers, benefit from simplified automation solutions tailored to their needs. This democratization of technology empowers a broader range of individuals to implement automation, streamlining processes in various settings including retail, logistics, and even personal tasks. By fostering collaboration between technical builders and everyday users, the robotics ecosystem is enriched, leading to practical applications that drive productivity at all levels.

Failure Modes and Challenges

While robotics and automation offer considerable advantages, it is vital to consider potential failure modes and challenges associated with these systems. Reliability issues can arise from software glitches, mechanical failures, or environmental factors, leading to unanticipated downtime. In many cases, neglecting regular maintenance can exacerbate these risks, resulting in costly repairs or replacements.

Cybersecurity is another critical concern, as interconnected robotic systems become attractive targets for cyberattacks. Companies must invest in robust cybersecurity measures to prevent unauthorized access that could compromise operational integrity. Furthermore, implementation misalignments can occur if there is insufficient training or support, leading to suboptimal use of the technology and wasted resources.

Cost overruns can also occur when deploying automated solutions, as initial budget estimates may not account for the full range of necessary infrastructure upgrades or the costs associated with training personnel. Successfully navigating these challenges requires a proactive approach, involving careful planning, regular monitoring, and adapting to unforeseen circumstances.

What Comes Next

- Monitor the development and adoption trends of collaborative robot solutions in small and medium-sized enterprises.

- Watch for new regulations being implemented concerning safety and operational standards in robotic systems.

- Track advancements in AI algorithms that enhance decision-making capabilities in automated systems.

- Observe emerging cybersecurity solutions tailored to protect interconnected robotic systems from vulnerabilities.

Sources

- ISO Standard for Collaborative Robots ✔ Verified

- NIST Robotics Standard ● Derived

- AI and Robotics in Industry Applications ○ Assumption