An Integrated Approach to Ceramic Analysis and Valuation

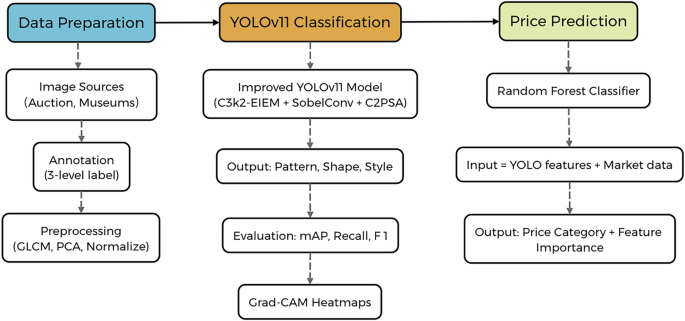

In the rapidly evolving world of ceramic appraisal, understanding the intricate details of each artifact is paramount. This study introduces a three-stage pipeline designed for robust ceramic analysis and price prediction, featuring dataset preparation, ceramic classification, and price prediction, as illustrated in Fig. 1. This integration ensures seamless functionality, allowing for a comprehensive examination of ceramics.

Stage 1: Dataset Preparation

Construction and Annotation of a High-Quality Database

The first stage focuses on creating and annotating a high-quality dataset of ceramic images. The database comprises 8,213 high-resolution photographs, showcasing 20 distinct craftsmanship styles. These styles were selected for their historical significance and visual uniqueness, with a representation of forms and production techniques that span various dynasties. Examples include Blue and White Porcelain, Doucai, and Ru Kiln artifacts, each embodying unique artistic styles. Due to their inherent differences in representation, the dataset experiences moderate class imbalance; well-represented types like Blue and White Porcelain have over 600 samples, while rarer categories like Ru Kiln have fewer than 100 images.

To rectify potential issues stemming from this imbalance, data augmentation strategies, including image rotation, flipping, and brightness adjustments, were employed specifically for underrepresented categories. This measure helped in generating a more uniform distribution during model training.

Image Sourcing

The images were collected from three main avenues:

- Auction Houses: Accounting for 42.6% of the dataset, major auction platforms like Christie’s and Sotheby’s served as key resources.

- Museums and Cultural Heritage Institutions: 24.3% of the images were obtained from esteemed institutions such as the Palace Museum and the British Museum.

- Field Photography: The remaining 33.1% of images stemmed from ceramic art stores, private collectors, and general photography platforms.

To uphold copyright regulations, automated web scraping and collaborative photography with ceramic experts were utilized, ensuring high-definition image quality.

Challenges and Solutions in Data Collection

Data acquisition did not come without its challenges. Among them were:

-

Lighting Issues: Light reflections and shadows on ceramics could distort the quality of photographs. To mitigate this, bilateral filtering was applied to maintain edge details while minimizing noise.

-

Background Complexity: Complex backgrounds often distracted from the main focus of the artifacts. Background segmentation algorithms, specifically GrabCut, effectively isolated the ceramics, thus enhancing the image quality.

- Resolution Inconsistencies: To maintain uniformity, all images were standardized to a resolution of 1024×1024 pixels.

Hybrid Annotation Approach

For data annotation, a hybrid technique combining AI pre-annotation and expert validation was employed. The YOLO pre-trained model facilitated initial object detection by generating automatic bounding boxes around the ceramics. Subsequently, a team of ceramic appraisal experts refined these annotations using structured guidelines.

Hierarchical Classification

The classification was organized into three hierarchical levels:

-

Craftsmanship Styles: Distinct craftsmanship styles were labeled based on characteristic features derived from authoritative museum collections and academic literature.

-

Vessel Shapes: Classification was established according to the physical characteristics of each ceramic piece. Borderline cases were resolved through group consensus.

- Decorative Patterns: Rather than detailing individual motifs, images were annotated based on the most visually dominant pattern types present in the overall design.

Further attributes like color complexity, structural intricacy, and estimated price range were also annotated to enrich the dataset. Annotation consistency was reinforced through a calibration phase with a final Cohen’s Kappa coefficient of 0.91, indicating strong inter-annotator agreement.

Stage 2: YOLOv11-based Classification

Advanced Object Detection with YOLOv11

The pipeline progresses to deploying a YOLOv11 model for classifying ceramic images. YOLO (You Only Look Once) facilitates both object localization and classification in a single pass, making it remarkably efficient for real-time applications like automating the classification of ceramic artifacts.

Why Choose YOLOv11?

- Real-Time Detection: The model’s end-to-end detection capabilities make it suitable for large-scale applications.

- Multi-object Recognition: The system can simultaneously identify multiple decorative elements present in a ceramic artifact.

- Efficient Inference: With YOLOv11, the integration of classification and detection saves time and resources, allowing for easier deployment on mobile platforms.

Architectural Enhancements

The improved YOLOv11 architecture consists of three critical components: Backbone, Neck, and Head.

-

The Backbone utilizes ResNet50 to extract features from ceramic images. The C3k2-EIEM module within the Backbone enhances edge detection and preserves spatial features, vital for accurately classifying intricate ceramic details.

-

The Neck optimizes feature aggregation, combining the top-down and bottom-up feature propagation strategies to capture ceramics’ varying scales effectively.

- The Head consists of multiple output branches optimized for detecting both large ceramic structures and fine-grained decorative features.

Training Protocols

Training involved using advanced data augmentation strategies like Mosaic and MixUp to enhance generalizability and robustness. A cyclic learning rate scheduler was employed, while early stopping helped prevent overfitting. The evaluation of the model is based on crucial metrics such as accuracy, precision, recall, and F1-score.

Stage 3: Regression-Based Price Prediction

The final stage shifts to predicting market prices based on feature extraction from the ceramic images. Rather than relying solely on traditional appraisal methods, which can be subjective, this study incorporates a Random Forest (RF) regression framework to enhance objectivity and systematization.

Classification-Based Approach to Pricing

While ceramic prices can be exceedingly continuous, this study adopts a classification-based approach for several practical reasons:

-

Skewed Auction Data: Traditional regression models often struggle with the outlier-heavy distribution of auction prices.

- Industry Standards: In the market, values are typically communicated in discrete brackets, simplifying the process for potential buyers and sellers.

Feature Structuring and Engineering

A structured feature engineering process emphasizes both categorical and numerical factors impacting ceramic valuation. Key features include decorative patterns, craftsmanship styles, kiln origins, and outlier handling to ensure stable model training.

Random Forest Model Architecture

The RF model operates through ensemble learning by building multiple decision trees, which enhances generalization and reduces overfitting. Key hyperparameters such as the number of trees, maximum depth, and minimum samples per leaf were systematically adjusted to optimize performance.

Conclusion

The outlined three-stage pipeline offers a comprehensive framework for ceramic classification and price prediction, merging intricate visual details with market dynamics. Through advanced machine learning techniques, this approach not only enhances the accuracy of ceramic artifact analysis but also contributes to the interpretability and understanding of their valuation in a complex marketplace.

This article provides an informative look into the innovative methods for ceramic analysis and valuation, showcasing the potential of integrating machine learning in cultural heritage studies.