“Adaptive Federated Multi-Scale Vision Transformer for Enhanced Industrial Defect Detection”

Federated Multi-Scale Vision Transformer with Adaptive Client Aggregation for Industrial Defect Detection

Understanding the Framework

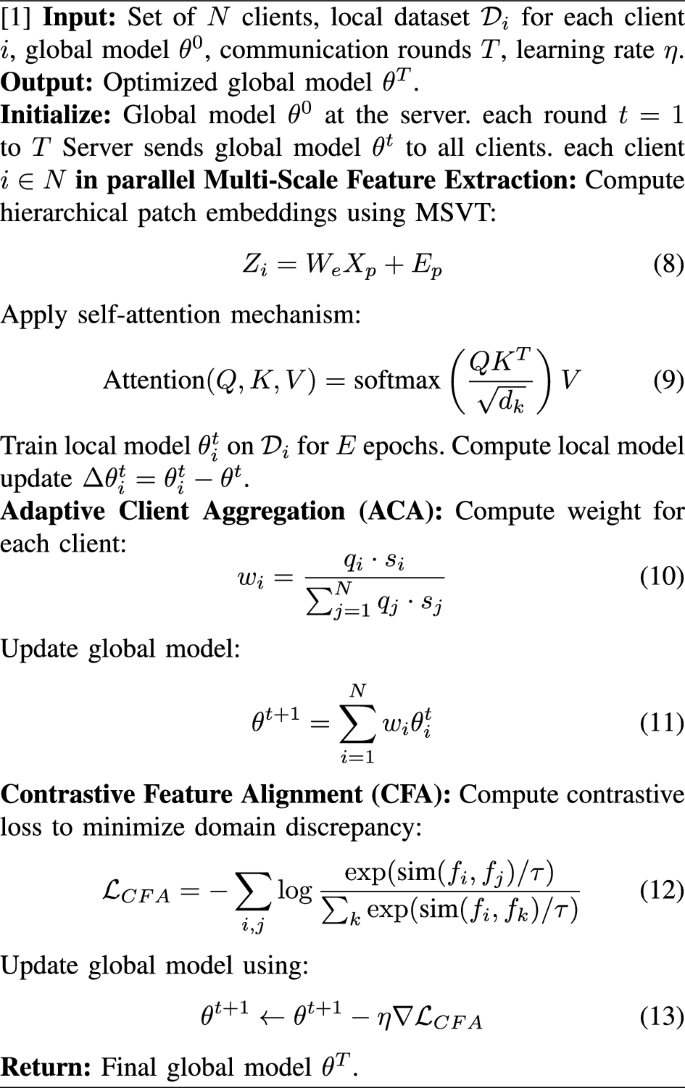

The Federated Multi-Scale Vision Transformer with Adaptive Client Aggregation (Fed-MSVT) is an innovative framework tailored for accurate and privacy-preserving defect detection in industrial settings. By leveraging federated learning principles, this approach allows multiple clients (or devices) to collaborate on model training without sharing sensitive data. Essentially, the model learns from decentralized data while ensuring that privacy is upheld.

This framework addresses the significant challenge of detecting defects in complex environments, where data privacy and diverse data distributions can complicate traditional machine learning methods.

Core Concepts

Multi-Scale Vision Transformer (MSVT)

At the heart of components is the Multi-Scale Vision Transformer (MSVT). Unlike conventional convolutional neural networks (CNNs), Vision Transformers excel at capturing long-range dependencies, yet they often fall short in precisely identifying local defects. The MSVT mitigates this limitation by processing images through various spatial resolutions, allowing for hierarchical representation of defects.

For instance, in industrial applications, defects may appear small and localized or be more substantial. The multi-scale approach ensures that the detection mechanism is sensitive to defects of various sizes, enhancing overall accuracy.

Adaptive Client Aggregation (ACA)

Traditional federated learning models, like FedAvg, utilize a standard averaging technique to combine client updates. However, this approach can be detrimental when working with non-IID (Independent and Identically Distributed) data and inconsistent client performances. To improve upon this, the Adaptive Client Aggregation (ACA) strategy assigns dynamic weights to clients based on three factors: data quality, update stability, and domain shift similarity.

Clients with high-quality data and stable updates contribute more to the aggregated model, enhancing robustness and accuracy. For example, if one client processes consistently accurate defect data, it would significantly influence the global model compared to less reliable updates.

Contrastive Feature Alignment (CFA)

One of the salient features of Fed-MSVT is Contrastive Feature Alignment (CFA). In industrial settings, variations in imaging conditions can lead to domain shifts that challenge model generalization. CFA addresses this by promoting the alignment of feature embeddings from similar (normal) samples while ensuring that anomalies are distinctly separated.

This is achieved through a contrastive loss function designed to cluster representations of normal samples closely while pushing anomalous samples apart in the feature space. Such an approach helps maintain effective separation, enhancing the model’s capability to distinguish between normal and defective samples.

Implementation Process

The lifecycle of implementing Fed-MSVT involves several phases:

-

Client Initialization: Various clients, from different manufacturing lines or facilities, initialize their local models based on their localized data.

-

Local Training: Each client trains its model using local data. Data quality is assessed based on local validation accuracy, which drives the subsequent weighting in the aggregation process.

-

Adaptive Aggregation: The clients share their model updates without disclosing their data. Each client’s contribution is weighted according to the aforementioned ACA strategy, assuring that more reliable models influence the global model disproportionately.

-

Global Model Update: The global model is updated by aggregating the weighted contributions of the local updates, ensuring that the final model is robust and can efficiently detect defects across diverse environments.

- Contrastive Learning: During training, the CFA module operates, aligning feature embeddings and enhancing the model’s understanding of both normal and defective states.

Practical Example

Consider a scenario in a factory where various machines produce electronic components. Each machine generates its local dataset containing normal and defective parts. By implementing Fed-MSVT, each machine can train on its own data—factoring in variances in production conditions—while contributing to a joint model that benefits from collective insights without compromising sensitive information.

After several training cycles, this collaborative framework can identify defects across various machines with enhanced reliability and accuracy, effectively adapting to shifting production dynamics.

Common Pitfalls

When deploying Fed-MSVT, organizations may face challenges such as:

-

Inconsistent Data Quality: Ensuring that all clients maintain a baseline level of data quality is crucial. If some clients provide poor-quality data, it can negatively influence the aggregated model.

-

Model Overfitting: With varying client data distributions, there’s a risk that the global model may become tailored to the most prevalent data patterns at the expense of underrepresented scenarios. Continuous evaluation and adjustment are necessary.

- Technical Overhead: Implementing federated learning can introduce complexities in system architecture and require robust computational resources to manage client-server communications and model updates.

Tools and Frameworks in Practice

In practice, various frameworks can facilitate the implementation of Fed-MSVT, including:

- PySyft and TensorFlow Federated for managing federated learning environments.

- Scikit-learn and Pytorch for model development and local training phases.

- Hyperparameter tuning tools such as Optuna to optimize model performance throughout the training process.

With a structured approach that incorporates the necessary tools and strategic adjustments throughout implementation, organizations can truly leverage the capabilities of Fed-MSVT for enhanced industrial defect detection.

Further Reading

For an in-depth study of the technical underpinnings and experimental results of this framework, refer to the original publication: Adaptative Federated Multi-Scale Vision Transformer for Enhanced Industrial Defect Detection. This work presents compelling evidence of the framework’s efficacy in real-world applications, boosting future advancements in smart manufacturing.