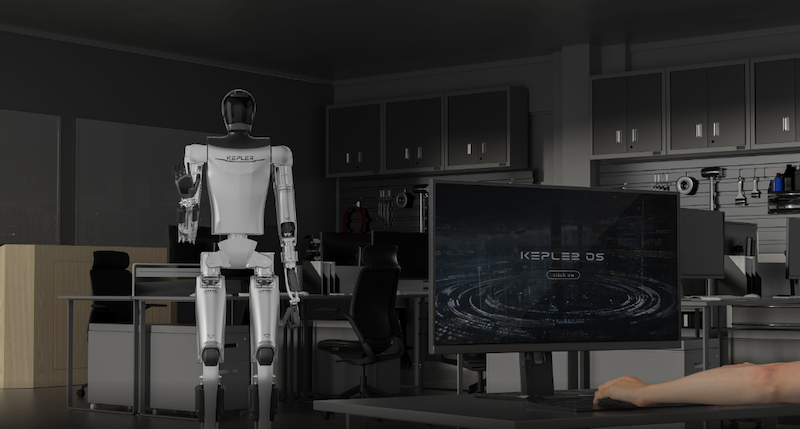

Kepler Robotics Launches K2 “Bumblebee”: A Milestone in Humanoid Robotics

Shanghai-based Kepler Robotics is making headlines with the mass production of its humanoid robot, the K2 “Bumblebee”. This marks a significant transition from mere research prototypes to large-scale deployment in the humanoid robotics industry, a move that is expected to reshape the market.

Kepler has already signed framework agreements for several thousand units, with contracts valued in the hundreds of millions of yuan. This ambitious rollout is an important milestone not just for Kepler, but for the entire global humanoid robotics sector.

Understanding Hybrid Architecture

The term “hybrid architecture” may sound technical, but it actually refers to the sophisticated mechanical and computational frameworks that make the K2 unique.

The K2 employs a combination of roller screw linear actuators and rotary actuators. This innovative blend enables the robot to achieve smoother, more stable movements, mimicking the fluidity of human motion while ensuring an extended operational lifespan.

On the computational side, the hybrid architecture integrates onboard processing with cloud-based capabilities. This dual setup allows the K2 to handle real-time tasks locally while turning to cloud servers for more resource-intensive operations like training and simulations. Kepler claims that this system achieves up to 81.3% energy efficiency, allowing for up to eight hours of operation on a single charge.

The robot also incorporates advanced learning techniques, such as reinforcement learning and imitation learning, which enable it to replicate human-like walking patterns with accuracy—capturing nuanced movements like heel strikes and toe-off actions.

Versatile Industrial Applications

The K2 is crafted for seamless integration into various industrial settings. With a dual-arm payload capacity of 30 kg, it can effectively engage in carrying, loading, and unloading tasks, making it a versatile asset on factory floors and logistics centers.

Additionally, the robot can perform assembly work and can be deployed for public demonstrations or specialized operations. Its semantic task-processing system allows it to understand and execute natural language commands—ideal for sorting tasks or guiding tours, adding a layer of user-friendliness that sets it apart.

Priced at RMB 248,000 (approximately $34,000), the K2 presents a cost-effective alternative to existing million-yuan prototypes in the market, thereby lowering the financial barrier for businesses looking to adopt this technology.

Building a Robust Ecosystem

Kepler views this product launch as the “first year of mass production” for humanoid robots, signaling the beginning of a new era. In their efforts to scale manufacturing, Kepler is collaborating with supply chain partners and strategic investors, including well-known names like Tao Motor and Friend.

According to the company, robots like the K2 Bumblebee can not only improve productivity but also enhance safety in high-risk operations and repetitive manufacturing tasks. This strategic push to build a broader humanoid robotics ecosystem indicates Kepler’s commitment to making automation accessible to a wider range of industries.

Through their innovative robotic designs and strategic partnerships, Kepler Robotics aims to pave the way for the future of humanoid automation, creating exciting possibilities in industries far beyond their original application.