Innovative Advances in Automated Welding: Panasonic’s Tawers G4 at Schweißen & Schneiden 2025

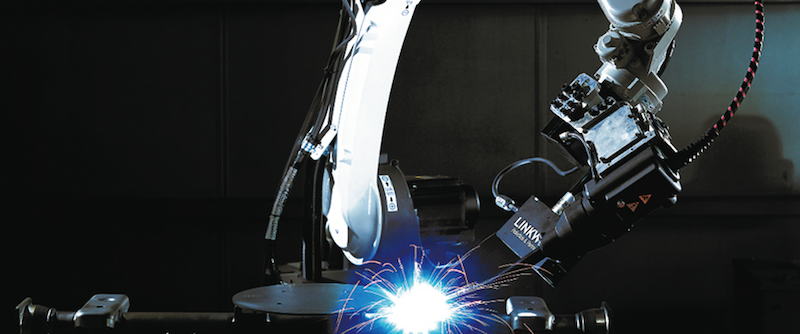

In a groundbreaking event set to captivate the industrial world, Panasonic Factory Solutions will unveil its latest advancements in automated welding technology at the Schweißen & Schneiden trade fair in Essen, Germany, from September 15 to 19, 2025. This year marks a significant evolution since the launch of the Tawers G4 Welding Robot System, showcasing impressive advancements in welding quality and operational efficiency.

Panasonic Tawers G4: The Cutting-Edge Welding Solution

The Tawers G4 Welding Robotic System represents the latest in integrated welding solutions, effectively blending advanced robot control with enhanced power source technology. This seamless system is meticulously designed to achieve maximum precision and reliability, delivering superb weld quality characterized by reduced spatter and shorter cycle times. Its user-friendly interface and real-time data feedback make it particularly well-suited for high-mix, high-volume production settings, allowing manufacturers to boost productivity while minimizing operational costs.

Live Demonstrations: Showcasing New Capabilities

Attendees at the fair will witness several live demonstrations showcasing the Tawers G4’s capabilities:

Argon-Rich Low-Slag Welding Process

One standout presentation will highlight the Argon-Rich Low-Slag welding process for mild steel. This innovative method employs a stable, argon-rich shielding gas mix alongside precisely controlled automation, resulting in exceptionally clean, high-quality welds. The process not only enhances productivity by saving time and reducing costs, but it also eliminates the need for specialized welding wires, making it ideal for high-throughput manufacturing environments.

AC TIG Welding Process for Aluminum

Another exciting demonstration will feature the Tawers AC TIG welding process for aluminum. This technique integrates precise waveform control with high welding speeds achieved through the pre-heating of the filler wire. The result delivers visually impeccable, spatter-free welds with minimal distortion, making it perfect for applications such as bicycle and motorcycle frames, tank construction, and furniture manufacturing. The advantages include excellent corrosion resistance and consistently high weld quality, catering to industries that demand precision.

Pulse Mix Process with Twin Harmonized Software

A third demonstration will introduce the Pulse Mix Process, utilizing synchronized dual-robot welding technology. This innovative approach means that one robot leads while the other follows, significantly reducing production time—by up to 50%. With a single teach pendant, operators can easily program both robots simultaneously, maximizing efficiency and user-friendly interaction.

Pioneering Solutions for Heavy Aluminum Welding

For the first time at a live event, Panasonic will display its capability for welding thick aluminum plates, featuring a Tawers WGH4 robot coupled with a DK-positioner in a fully automated cell. This system can weld 16-22mm thick aluminum using a robust 500A power source, achieving high penetration without the need for helium. This innovation not only cuts costs but also mitigates environmental impact, expanding opportunities for manufacturers engaged in demanding sectors like shipbuilding and offshore construction.

Tackling Industry Challenges with the Zi-Tech Process

Panasonic will also present the Zi-Tech process, designed specifically for automotive underbody parts. This new Zi-Pulse methodology addresses the challenges of welding zinc-galvanized plates, significantly diminishing issues like porosity, burn-through, and other defects that can compromise structural integrity. This process delivers cleaner, stronger welds, ensuring that production meets rigorous industry standards while reducing labor and material costs.

Simplifying Robotic Welding with Navigation Plus Software

Lastly, the introduction of Welding Navigation Plus aims to enhance the user experience further. Building on the original Weld Navi tool, this upgraded system automates the setting of optimal welding parameters based on critical factors like material thickness and speed. Moreover, users can easily adjust penetration depth and weld geometry, making robotic welding accessible even to those without prior welding expertise.

Panasonic’s Vision for the Future of Welding

As stated by Sergio Maeda, the head of the robot and welding department at Panasonic Factory Solutions Europe, this event promises to showcase a new wave of welding innovations designed for cleaner, faster, and more consistent welds across diverse applications. Manufacturers are increasingly turning to the Tawers G4 platform not just for unmatched weld quality but for its fully integrated systems and ease of use—an approach that effectively future-proofs their production capabilities.

Conclusion

The innovations presented by Panasonic at the Schweißen & Schneiden trade fair will undoubtedly shape the trajectory of automated welding in coming years. With their commitment to providing intuitive automation, Panasonic is making significant strides in enhancing quality, efficiency, and accessibility in the welding industry.