Most farms still rely on the antiquated method of manually weighing pigs with stationary scales. This labor-intensive process involves several farm workers lifting each pig onto the scale, holding it still, and waiting for the weight to be displayed— an experience that can be physically taxing and stressful for both the workers and the animals.

“When you stress the pigs, they lose a little bit of growth. So in one way, you decrease the parameters that are important for the profitability of the farm,” says Sylvain Longchamps, head of Animals Development at Barkom Ltd, an agricultural leader focused on pig and cattle production.

However, with the rapid development of agritech solutions, there’s a promising opportunity to revolutionize the weighing process into something more efficient, automated, and accurate. One groundbreaking technology leading this transformation is computer vision.

Benefits Computer Vision Brings to the Weighing Process

Employing computer vision technology means that the traditional weighing process can become entirely contactless. Farm workers no longer need to manually transport large animals to stationary scales; they just require a camera and smart algorithms. This non-invasive method alleviates stress not only from the weighing process itself but also contributes positively to the animals’ well-being and the quality of the meat produced.

“The computer vision technology can help determine whether an animal’s weight is appropriate or needs adjustment,” states Lou Dutko, chief technology officer at Lemberg Solutions. This enables farmers to manage livestock growth more effectively.

With real-time weight data at their fingertips, farmers can make informed nutritional adjustments or address potential health issues. In many markets, pigs need to meet specific weight criteria for slaughter, and this technology streamlines the selection process, allowing efficient planning for shipments to processing facilities.

Additionally, a portable computer vision device drastically reduces workload. Tasks that once required multiple workers can now be accomplished by a single farmer, shaving down weighing time by a factor of 24. In an industry grappling with labor shortages, this time-saving benefit is invaluable.

Furthermore, this solution aids veterinary care on farms. Veterinarians equipped with the device can assess a pig’s weight independently, quickly calculating the precise dosage of medication needed, thus enhancing animal welfare.

How Computer Vision-based Pig Weighing Works

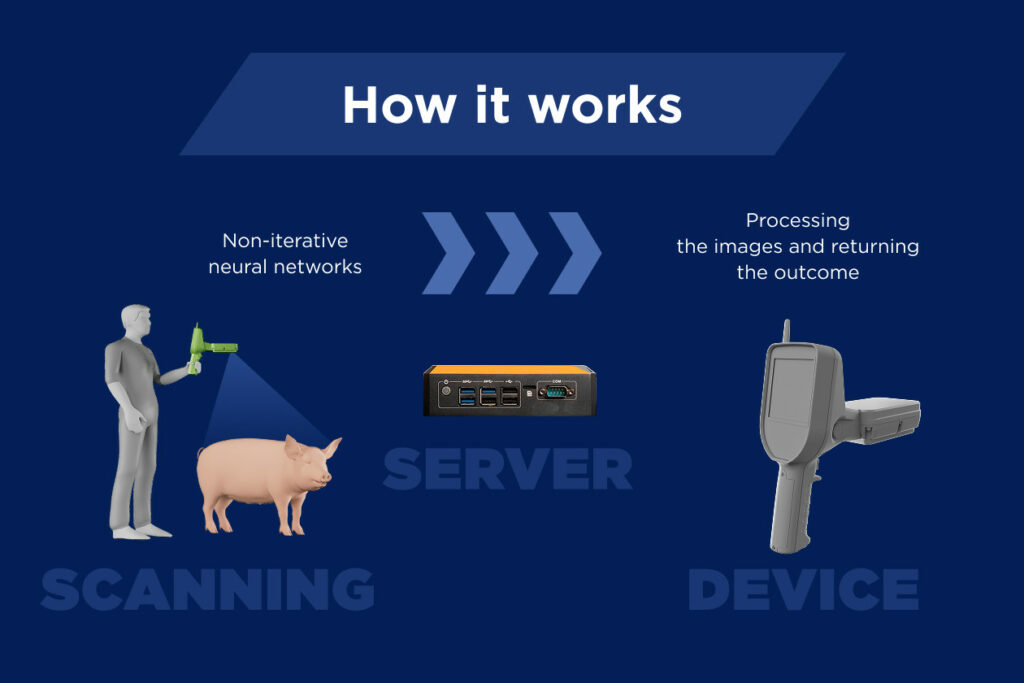

Let’s delve deeper into how a computer vision-based portable device operates in a farm environment. The system utilizes an advanced camera that captures 3D images of pigs in one snap, ensuring consistent quality even in challenging lighting conditions or if the animal is in motion. This portability means farmers can easily move around the farm with the device, capturing images of pigs from any location.

Once captured, the images are uploaded to a server for analysis via a specialized weight recognition algorithm. By employing sophisticated neural networks combined with custom image recognition software, the system evaluates a pig’s body shape and estimates its weight within a matter of seconds. The found weight is then relayed back to the device with just a 1-2% margin of error.

The success of such estimations hinges on the quality and richness of the database used to train the algorithms. A stationary device was installed above a waterer in the pen to collect images of pigs drinking while their weight was measured using scales. This method generated a database of 17 terabytes of data, allowing the weight estimation to achieve 98% accuracy.

“We monitored animal behavior and refined our equipment to identify the optimal moments for data capture to ensure the highest precision,” states Lou Dutko, discussing the meticulous setup for collecting reliable measurement data.

The practicality of this weighing solution lies in its capacity to integrate seamlessly into an existing farm infrastructure, ensuring minimal disruption to established operations.

“Weighing animals isn’t the most engaging task for farm workers, and it can be quite laborious. By automating this task, your top staff can devote more time to essential responsibilities like ensuring animal health,” concludes Sylvain Longchamps, highlighting the broader impacts of this innovative solution.