13 Must-Know Robotics Companies in the Automotive Industry

13 Must-Know Robotics Companies in the Automotive Industry

Understanding the Role of Robotics in the Automotive Industry

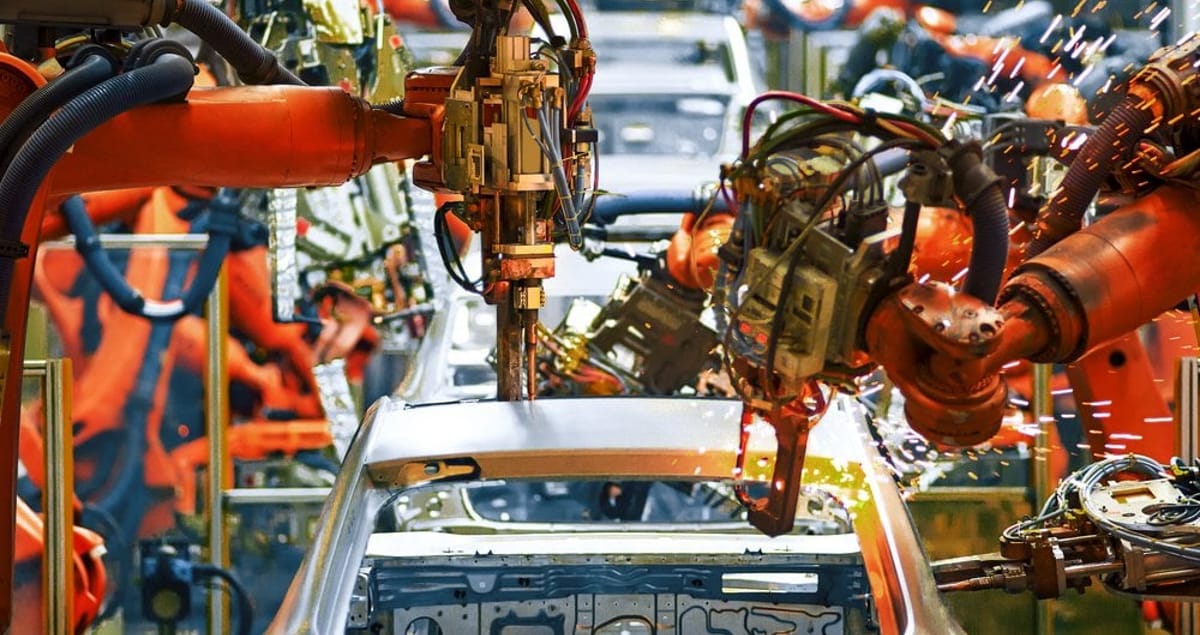

Robotics plays a critical role in advancing the automotive industry by improving efficiency, precision, and safety in manufacturing processes. By integrating robotic automation, companies can rapidly increase productivity while reducing operational risks.

Example: Automation in Assembly Lines

In automotive manufacturing, companies like Tesla are employing robotic automation to streamline assembly lines, wherein robots perform tasks such as welding, painting, and assembling components. These automated processes enhance throughput and ensure consistent quality.

Structural Model: Automation in Manufacturing Workflow

Diagram: A workflow diagram illustrating the interaction between human workers and robots in an automotive assembly line, showcasing the sequence of tasks and the feedback loops involved.

Reflection

What assumption might automotive professionals overlook regarding the limitations of robotic capabilities on the assembly line?

Practical Insight

Automotive manufacturers can benefit by investing in training programs for workers that focus on collaborating with robots, optimizing human-robot interaction to capitalize on collective strengths.

Key Robotics Companies Shaping the Automotive Landscape

-

ABB Robotics

ABB Robotics specializes in industrial robots and offers advanced automation solutions for various industrial sectors, including automotive. Their robots are known for flexibility and precision.Example: ABB’s IRB 6700 robot can adapt to different tasks, allowing automotive manufacturers to switch production lines with minimal downtime.

Reflection: How do different levels of automation impact worker satisfaction and productivity?

Practical Insight: Assessing the balance between automation tools and employee roles can lead to improved workflow and enhanced job satisfaction.

-

KUKA

KUKA stands out with its collaborative robots (cobots) that can work alongside humans safely.Example: KUKA’s LBR iiwa model is designed for sensitive assembly tasks, allowing human workers to assist robots without the need for safety cages.

Reflection: Would integrating cobots alter the skill sets required for automotive assembly workers?

Practical Insight: Companies should consider redefining job roles and creating continuous learning opportunities to foster a versatile workforce.

-

FANUC

FANUC is known for its strong presence in the robotics sector, particularly in industrial automation for automotive.Example: The FANUC M-20iA series enables rapid material handling and assembly operations, improving overall production efficiency.

Reflection: What cultural shifts might occur in organizations that heavily invest in robotic automation?

Practical Insight: Leaders should proactively manage change by promoting an innovation-friendly culture that encourages feedback.

-

Yaskawa

Yaskawa produces a range of industrial robots that excel in speed and precision.Example: Their Motoman series of robots facilitate tasks from welding to painting, ensuring automotive products meet quality standards.

Reflection: How do variations in robot specifications affect job safety in automotive manufacturing?

Practical Insight: Regular safety audits aligned with robotic capabilities can mitigate risks during production.

-

Universal Robots

Universal Robots is a pioneer in developing collaborative robotic solutions.Example: Their UR3 robot can enhance flexibility in small-scale automotive assembly tasks while working harmoniously with human workers.

Reflection: Are there any scenarios where human intuition could outperform robotic efficiency in complex assembly tasks?

Practical Insight: Emphasize the unique advantages of human expertise in areas requiring creativity or critical judgment.

-

Boston Dynamics

Known for its agile and adaptable robots, Boston Dynamics is advancing the robotics industry.Example: Their robot Spot can navigate complex environments, potentially transforming automotive testing environments.

Reflection: What ethical considerations arise when deploying robots in real-world scenarios?

Practical Insight: Companies should establish ethical guidelines that address the deployment of advanced robotics in testing.

-

Siemens

Siemens integrates robotics within smart manufacturing solutions, enhancing automated processes.Example: Siemens’ MindSphere allows manufacturers to connect machines, enabling data-driven decision-making on assembly lines.

Reflection: How could data analytics change the perception of automation in the automotive sector?

Practical Insight: Fostering a data-savvy culture can leverage insights from automation tools for continuous improvement.

-

NVIDIA

Specializing in AI and deep learning, NVIDIA impacts robotics through AI-driven solutions.Example: NVIDIA’s Jetson platform empowers automotive robots with advanced perception capabilities for better navigation.

Reflection: How might AI integration redefine roles in automotive manufacturing?

Practical Insight: Enhance AI literacy to prepare teams for future trends driven by autonomous technologies.

-

Rethink Robotics

Focused on collaborative robots, Rethink Robotics aims to simplify production processes.Example: Their Sawyer robot can adapt to varying tasks within automotive assembly, making it a versatile tool.

Reflection: In what ways can flexibility in robotics drive innovation in design and production techniques?

Practical Insight: Empowering teams to leverage robotic flexibility could lead to groundbreaking product designs.

-

Robot System Products

Known for offering a range of robot components, RSP emphasizes modular designs.Example: Their modular grippers can quickly adapt to different automotive components, enhancing the assembly process.

Reflection: What potential disruptions might arise from modular robotics during production ramp-ups?

Practical Insight: Analyzing modularity can prepare teams for rapid changes in production requirements.

-

Fanuc Robotics

A leader in automation solutions, Fanuc’s robots are renowned for their reliability.Example: Fanuc’s collaborative robots are utilized in assembly areas of automotive manufacturing to minimize errors.

Reflection: What trade-offs exist between traditional robots and collaborative robots in terms of productivity?

Practical Insight: Executives should weigh the benefits of initial costs versus long-term productivity gains.

-

Kawasaki Robotics

Pioneering industrial robotics, Kawasaki enhances automotive assembly.Example: Their dual-arm robot can handle complex tasks that require intricate movements on the assembly line.

Reflection: How can the utilization of dual-arm robots change interactive processes between machines and operators?

Practical Insight: Developing training programs tailored to dual-arm robotics can optimize workflow and minimize errors.

-

Omron Robotics

Focusing on flexible automation, Omron integrates robots into diverse automotive applications.Example: Omron’s mobile robots provide real-time inventory management, drastically improving logistics.

Reflection: How might mobile robotics alter traditional inventory management strategies?

Practical Insight: Implementing mobile RFID technologies alongside robotics can improve inventory accuracy.

This exploration of key robotics companies reveals the intricate landscape of automation in the automotive industry. Each firm’s contributions underscore the potential of robotics to enhance productivity while shaping a resilient workforce ready for future technologies.